1200W Closed Loop Servo Motor and Driver for Financial Machinery, Automated Production Line

Features

GH-11120DC is 1200W and high of rotation speed with 3000RPM, and 4NM servo motor,optimum matching with our AC servo driver to real ize optimum servo performance.

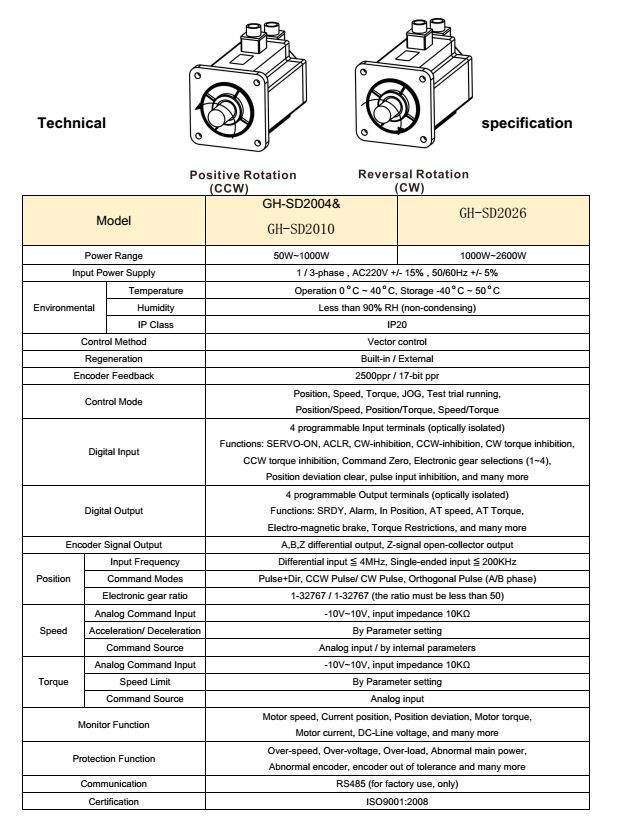

The match servo driver, GH-SD2026,SZGH-201,GH-301, that matching for 1200W servo motor.

There is also one dual servo driver,GH-302,that can control two pcs of 1200W servo motors synchronously.

Related Model : GH-11120BC

Application

CNC Machinery,printing equipment, packaging equipment, textile equipment, laser processing equipment, robotics, automated production lines, such as processing precision, processing efficiency and reliability, and other requirements of the relatively high equipment.

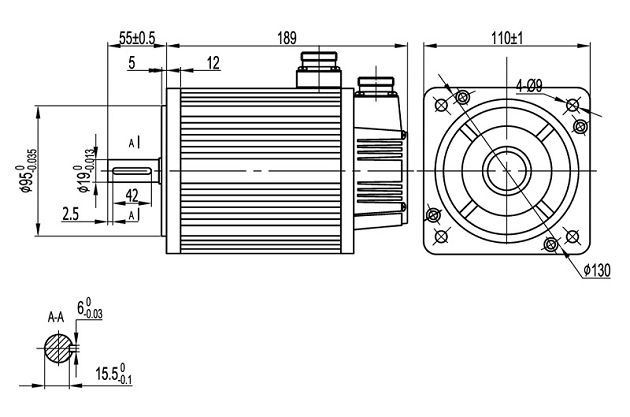

| Motor Model | SZGH-11060DC |

| Rated Power(W) | 600 |

| Rated Voltage(V) | 220 |

| Rated Crrent(A) | 2.5 |

| Rated Speed(RPM) | 3000 |

| Rated Torque(NM) | 2 |

| Peak Torque(NM) | 6 |

| Voltage Constantv10r/min | 56 |

| Torque Coefficient(NM/A) | 0.8 |

| Rotor Inertia(Kg.m²) | 0.54*10 |

| Line-Line Resistance(Ω) | 1.09 |

| Line-Line Inductance(mH) | 3.3 |

| Machanical Time-Constant(Ms) | 3 |

| Encoder Resolution(PPR) | 2500 |

| Insulation Class | Class B |

| Safety Class | IP65 |

| The Operating of Evironmental Condition | Temperature:-20℃~+45℃ Humidity Below 90%RH(No drawing) |

| Weight(KG) | 6 |

FAQ

Q: How long is your delivery time?

A: The general delivery time is 4-6 days after receiving your order confirmation. , if we have the goods in stock, it will only take 1-2 days.

Q: Do you provide sample ? Is it free?

A: If the sample is low value, we will provide the free sample with freight collect. But for some high value samples, we need to collect the sample charge.

Q: What is your term of payment?

A: 50% down payment before producing and 50% balance payment before shipping.

If you have another question, pls feel free to contact us as below