Number of control axes | 5 Axis |

Minimum programming | 0.001mm |

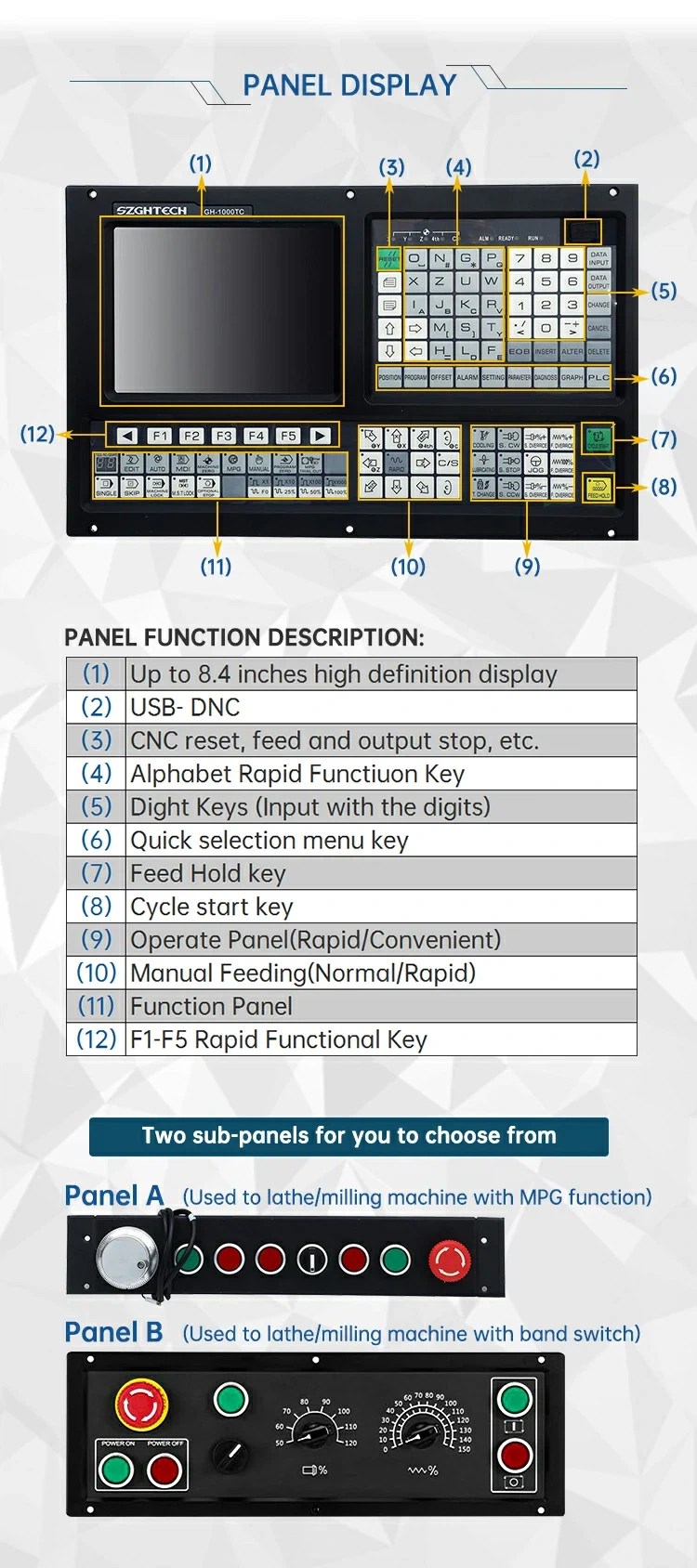

| Display | 8.4 inch color screen |

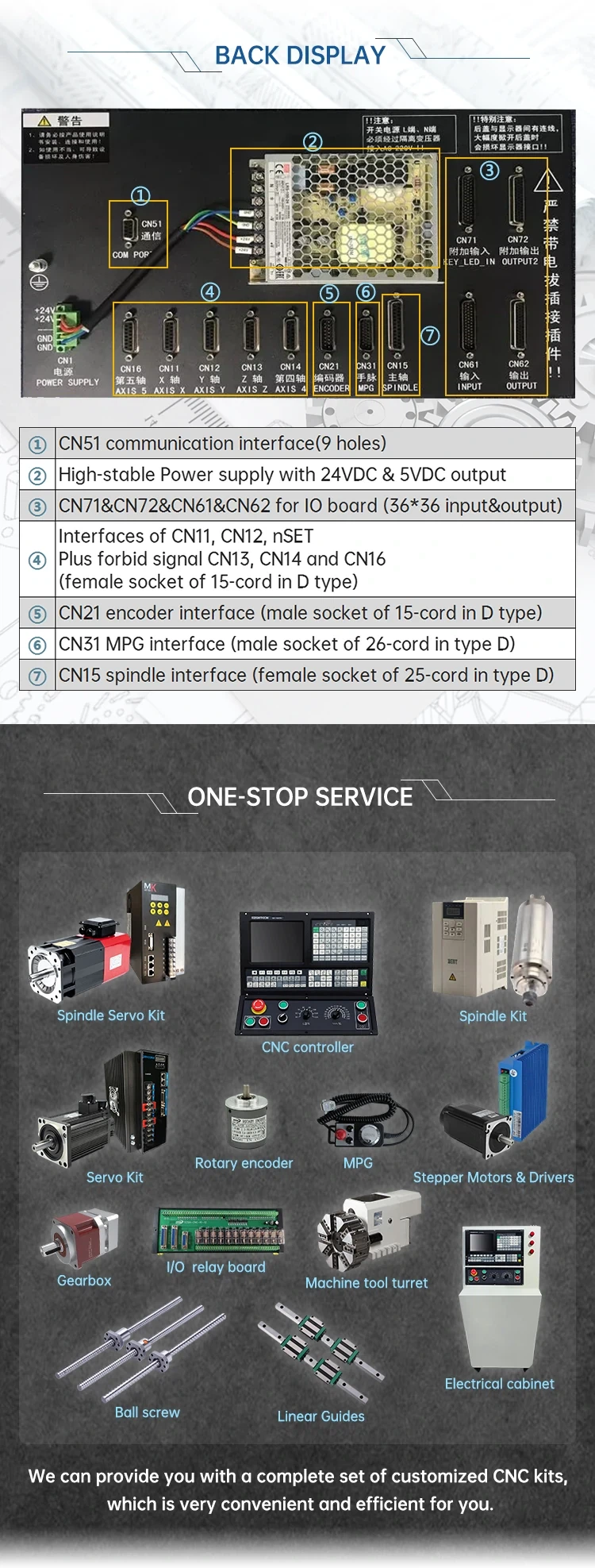

| interface | USB+RS232 Communction Port |

Maximum programming | ± 99999.999mm |

Top speed | 30m / min |

Feed speed | 0.001-15m / min |

Spindle functions | Gear, dual analog control, rigid tapping |

Pre-reading function | Short line preprocessing 10,000 lines |

| Function | ATC+PLC and macro function |

| Encoder lines | Any setting |

| User macro program | Yes |

| Our Services | 12 Months warranty;Provide professional CNC solutions; |

| Compensation function | Knife compensation, between compensation, screw compensation, radius compensation |

| Security function | Emergency stop, hardware travel limit, various stored travel checks, axis interlock, data backup and recovery |

| Program storage and editing | 1) Program capacity: 100M, 10000 programs (including subprograms, macro programs) 2) Editing method: full-screen editing, supporting background editing of part programs 3) Editing functions: program/program segment/word retrieval, modification, deletion, block copy/block deletion 4) Program format: Two sets of G code commands are optional, no spaces between command words are supported, and mixed programming of relative coordinates and absolute coordinates is supported 5) Program call: support macro program call with parameters, support 12 levels of subprogram nesting |

FAQ

Q: Do you support customized manufacturing?

A: Yes,we can customized manufacturing according to customer's requirment. We support to OEM

your own company display interface and logo.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample with sample price.

A: Generally it is 3-5 days if the goods are in stock. or it is 5-10 days if the goods are not in stock, it is according to quantity.10-20 days if customized manufacturing.

If you have another question, pls feel free to contact us as below.