Szgh-CNC1000mdb-3 CNC Milling 3 Axis CNC Kit CNC Control Servo Motor Kit For Heavy Milling Machine Milling Controller

COMPANY PROFILE

Company Profile

We are a manufacturer of CNC systems and machines with more than ten years of industrial experience. We have been committed to providing customers with the best industrial automation solutions. Our company is clearly structured and includes R&D, production, sales and technical support departments to ensure that we can provide the best possible service.

Our products and services include CNC machines, control system, supporting software and training services. Our items are suitable for a wide range of industries and fields. Our software and training services help customers get up to speed quickly and understand the best way to use their products.

You can please contact us anytime if you have any needs&demands!

OUR SERVICE

1.CERTIFIED ACTUAL PRODUCTS

We have a zero-tolerance policy for asset recovery vendors.

2.PROFESSIONAL TECHNICAL ENGINEER TEAM

A:Possible fastest response and support to clients' application demand

3.UALITY GUARANTEE

A: One-years warranty and life-long maintenance.

4. FAST. PROFESSIONAL AND RELIABLE INTERNATIONAL DELIVERY

A:Flexible and low cost delivery solution for clients.

FAQ

1. Who are we?

We are based in Guangdong, which providing cnc total solutions&Robot arm, sell to EastermEu-rope(20.00%), Mid East(20.00%), Southeast Asia(15.00%), Southem Europe(10.00%), SouthAmeri-.ca(8.00%), North America(5.00%),Western Europe(5.00%), Eastern Asia(4.00%), CentraAmeri-ca(4.00%), Northern Europe(4.00%),Africa(3.00%), Domestic Market(2.00%).

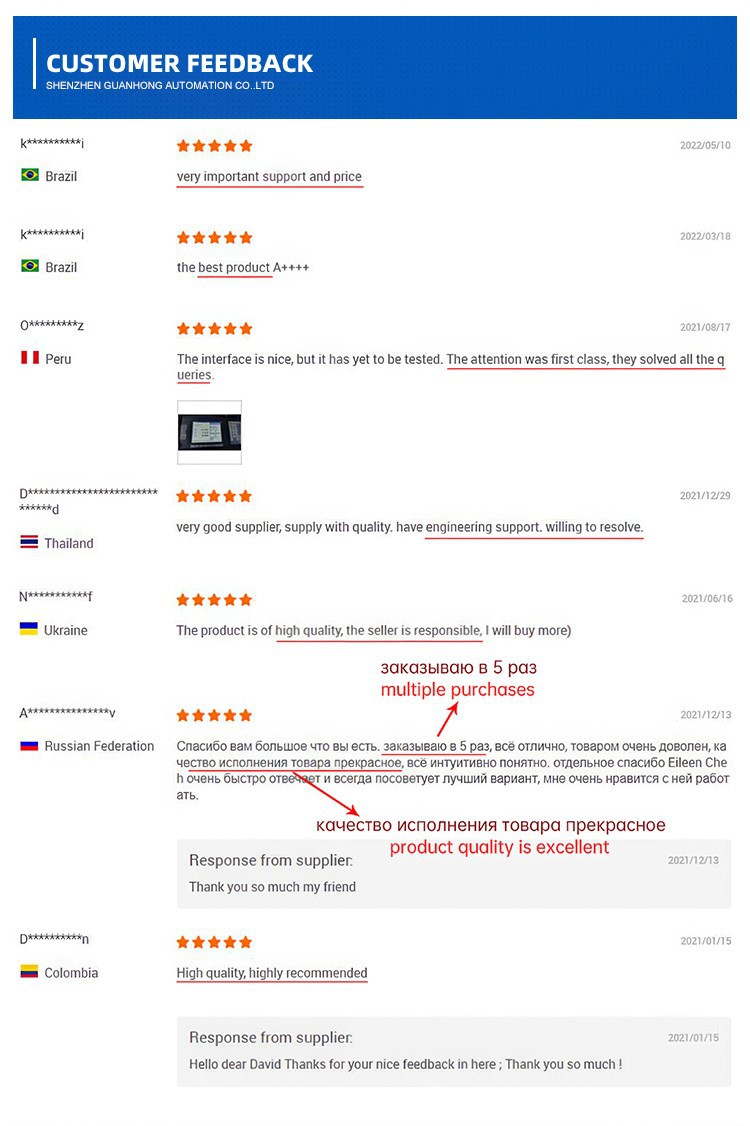

2. How can we guarantee quality?

Always finishing a pre full testing by our professional engineers;Always final 100%Inspection before shipment.

3.Could you supply total cnc system?

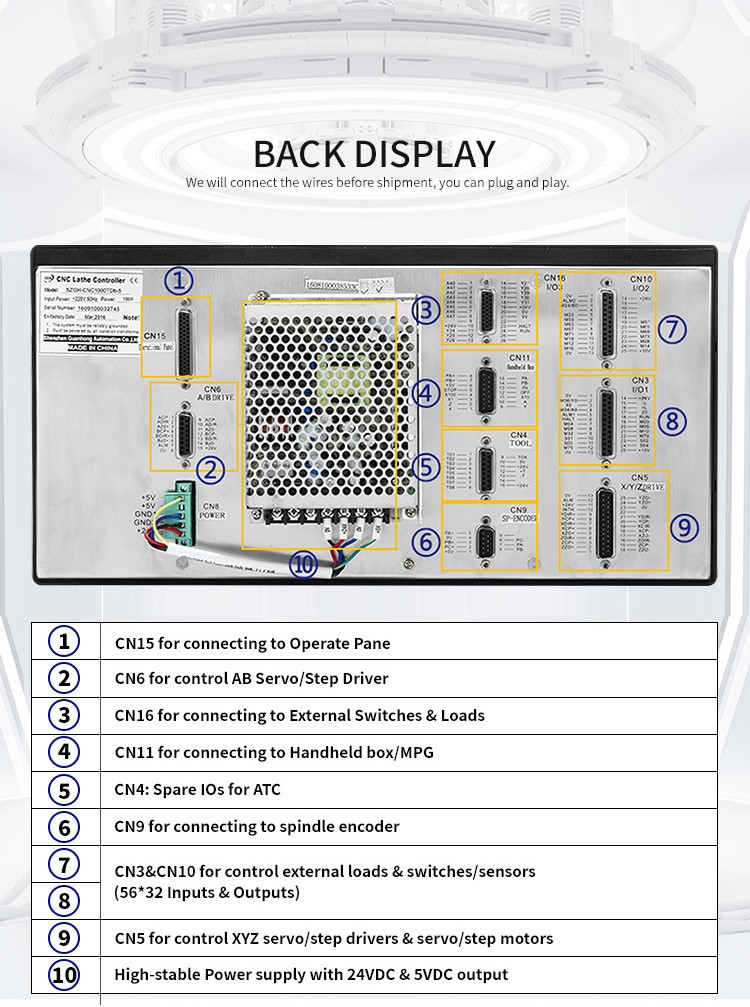

We can supply total cnc system, includes CNC controller, Spindle drivers & motors, Axes drivers&motors & related cables & kits, so you can plug and play.

4. What services can we provide?

1).Accepted Delivery Terms: FOB, CFR, CIF, EXW, FAS, CIP, FCA, DDP, DDU, DAF

2).Accepted Payment Currency: USD,EUR, CAD, HKD, CNY;

3).Accepted Payment Type: T/T, L/C, D/P D/A, Credit Card, PayPal, Western Union, Cash,Escrow,

4).Language Spoken:English,Chinese,Spanish,Japanese,Portuguese,German,Arabic,French,Russian,Korean,ltalian andsoon.

5.When can you receive our order?

All goods will be produced well within 5 to 7 workdays, except the customized products.

6.What is control mode for feeding Axes?

Our Normal CNC support Pulse+Direction signals for feeding axes drivers;Our Modbus CNC supporEtherCAT/Powerlink modbus for feeding axes drivers.

7.What is control mode for spindle axes?

There are dual analog voltage outputs(0-10V) for speed control of spindle axis. Our Modbus CNCalsosupport Pulse speed spindle, also can use pulse to control speed of spindle servo system.

8.Does vour cnc support ATc function?

Yes, our CNC lathe system can support most of turret, like Eletric turret,servo turret,counting tur-ret,etc;We can edit special macro program & plc for special turrets also,And our CNC milling systemsupport Linear type , umbrella type, arm type, turret type tool magazines.

9.Does vour cnc support booting logo exchange?

Yes