SZGH’s CNC milling machine Advantage: Quality Meets Affordability

For decades, many overseas buyers have associated high-end CNC machines with European or Japanese brands. However, this perception is rapidly changing. Modern Chinese CNC manufacturers like SZGH have redefined industry standards by combining advanced engineering, cost efficiency, and responsive service. Today, Chinese CNC machines are not just an economical choice—they are a strategic investment for manufacturers in Southeast Asia, Europe, South America, and the Middle East.

The reason behind this shift is clear: China’s unique industrial ecosystem. The nation has built a complete CNC supply chain—from raw materials and core components to software and after-sales support. This enables companies like SZGH to offer high-quality machines at a fraction of the cost of Western counterparts, while maintaining precision and reliability that meet global standards.

Introducing the SZGH-650 vertical machining center: Compact Power, Big Results

The SZGH-650 Small CNC Milling Machine is designed for workshops and factories seeking high efficiency and versatility in a compact footprint. Despite its small size, the SZGH-650 vertical machining center delivers impressive machining performance that rivals larger and more expensive models.

SZGH-650 vertical machining centerProcessing Capabilities:

- Max Drilling Diameter: Aluminum Φ35mm / Steel Φ25mm (up to Φ55mm optional)

- Max Tapping Diameter: Aluminum M25 / Steel M18 (up to M20 optional)

- Max Milling Cutter Diameter: Φ100mm

- Max Spindle Speed: 6,000 rpm (optional 24,000 rpm electric spindle)

- Spindle Motor Power: 5.5kW (optional 7.5kW)

- Travel Range: X: 500mm, Y: 400mm, Z: 300mm

- Repeatability: 0.01mm

These specifications allow the SZGH-650 vertical machining center to handle a wide variety of materials—including aluminum, copper, stainless steel, and iron—with precision suitable for the automotive, mold, aerospace, and electronics industries.

Built for Precision, Stability, and Speed

Every component of the SZGH-650 vertical machining centerhas been engineered for accuracy, durability, and efficiency. The machine adopts a heavy-duty anti-deformation base, ensuring stable movement even at high speeds. Its BT40 spindle and 10-station servo tool magazine enable fast tool changes and continuous operation, minimizing downtime and maximizing throughput.

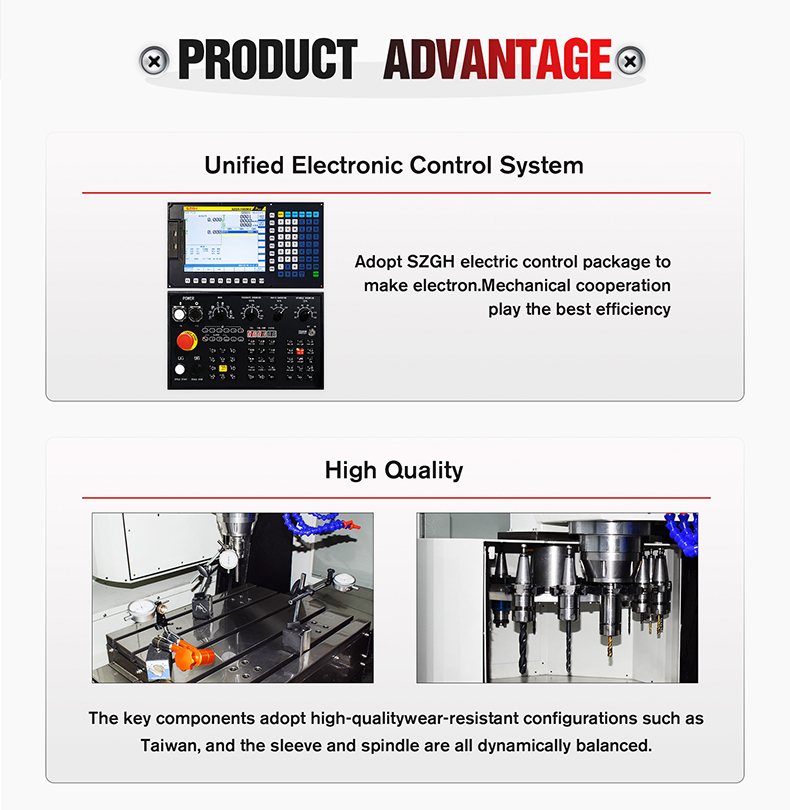

SZGH-650 vertical machining center is equipped with high-precision linear guide rails, advanced vibration suppression design, and SZGH’s proprietary CNC control system, which integrates high-speed interpolation, smooth surface machining, and user-friendly programming. These features ensure that even complex 3D profiles can be milled with perfect surface finishes and tight tolerances.

Why Overseas Buyers Choose SZGH Milling Machines

1. Buy a milling machine with excellent cost performance

One of the greatest advantages of Chinese CNC machines is their unmatched cost-performance ratio. The SZGH-650 offers performance comparable to global brands but at a significantly lower price. This allows overseas buyers to expand capacity or upgrade equipment without heavy financial pressure.

2. Advanced Technology, Local Manufacturing

While components such as spindles, servo systems, and guide rails meet international standards, most are locally produced in China under strict quality control. This reduces lead times, guarantees part availability, and lowers maintenance costs.

3. SZGH Milling Machines Smart and User-Friendly Operation

SZGH’s machining manufacturers integrated CNC control package provides intuitive operation for both beginners and experienced machinists. The system supports multiple programming languages and advanced simulation tools, making it ideal for global users.

4. Sustainability and Efficiency

The SZGH-650 vertical machining center consumes less power, produces minimal vibration, and offers excellent chip removal and coolant circulation systems. This eco-friendly design reduces operating costs and aligns with modern sustainability goals.

SZGH vertical machining center Global Service, Local Support

For many overseas customers, after-sales support is the key concern when purchasing from abroad. SZGH addresses this with a comprehensive global service network that ensures rapid technical response and spare parts delivery.

Through long-term cooperation with regional distributors and technical partners, SZGH provides remote diagnostics, online support, and on-site training to minimize downtime. Even customers thousands of kilometers away can enjoy the same service quality as those in China.

Real-World Applications: From Precision Molds to High-Speed Machining

The SZGH-650 has proven itself in diverse industries worldwide. In Southeast Asia, it is popular for small mold and die workshops requiring flexible and accurate machining. In Europe, it supports high-speed engraving and prototype manufacturing. In South America, many customers use the SZGH-650 vertical machining center for automotive components and electronic housings, benefiting from its reliability and low maintenance requirements.

Across all regions, users consistently report higher productivity, smoother finishes, and lower operating costs compared with previous generation machines.

The Secret Behind Quality and Affordability

SZGH’s advantage lies in its integrated production philosophy. Unlike many OEM factories, SZGH designs, manufactures, and assembles its CNC systems in-house—from the control boards to the mechanical base. This vertical integration ensures consistent quality, tighter cost control, and faster innovation cycles.

Furthermore, SZGH collaborates with top Chinese component suppliers for spindles, servo drives, and guide rails, all of which meet CE and ISO standards. The result is a machine that performs reliably under intensive workloads while remaining affordable for small and medium enterprises.

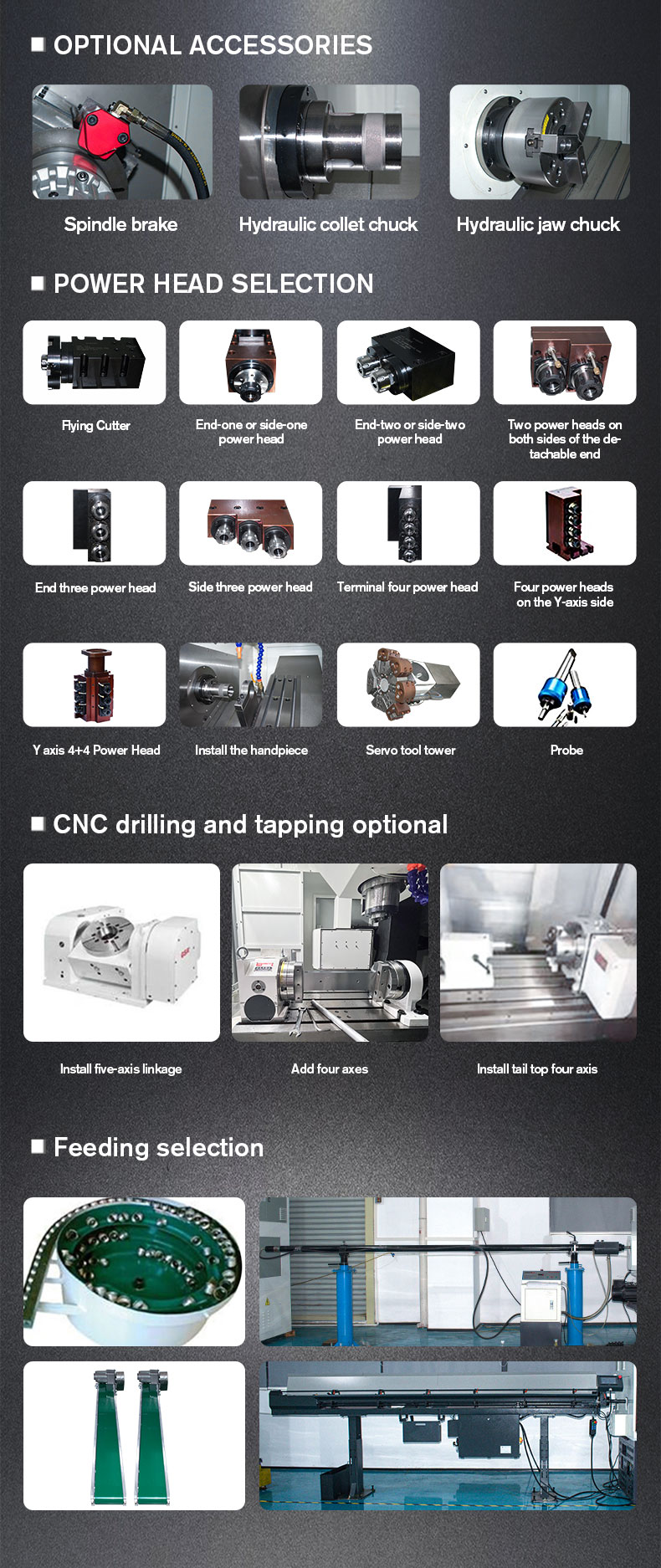

SZGH Seamless Communication and Customization

Language or distance is no longer a barrier. SZGH’s international sales and engineering teams provide multilingual communication, detailed technical documentation, and customization services. Whether you need special fixturing, additional spindle speed, or a customized control interface, SZGH engineers can tailor the SZGH-650 vertical machining center to your exact needs.

This flexibility is one reason many overseas OEM manufacturers choose SZGH as a long-term equipment partner.

Building the Future of Global Smart Manufacturing

As manufacturing continues to evolve toward automation and digitalization, SZGH remains at the forefront of smart CNC technology. The SZGH-650 vertical machining center embodies the company’s commitment to combining precision, reliability, and innovation in every detail.

SZGH-A Reliable Partner You Can Trust

Purchasing equipment from overseas requires confidence, and SZGH understands that trust is built on performance and service. Over the past decade, SZGH has established a reputation for reliability, transparency, and technical excellence.

Its customers range from small workshops to large industrial manufacturers who value SZGH for providing more than just machines—they provide complete machining solutions that help businesses grow.

Conclusion: The Smart Choice for Global Manufacturers

The global manufacturing landscape is changing rapidly, and companies are seeking partners who can deliver both value and innovation. With the SZGH-650 vertical machining center, Shenzhen Guohong (SZGH) Technology offers precisely that—a CNC milling machine that combines Chinese engineering strength, international quality, and responsive global service.

About SZGH Technology

Founded in Shenzhen, China, Shenzhen Guohong (SZGH) Technology Co., Ltd. is a leading manufacturer of CNC control systems, industrial robots, and intelligent automation solutions. With a strong focus on innovation, reliability, and customer success, SZGH has become a trusted partner for precision manufacturers around the world.

Brand Slogan:

"Shenzhen Guohong (SZGH) Technology — Empowering Smart Manufacturing Worldwide."