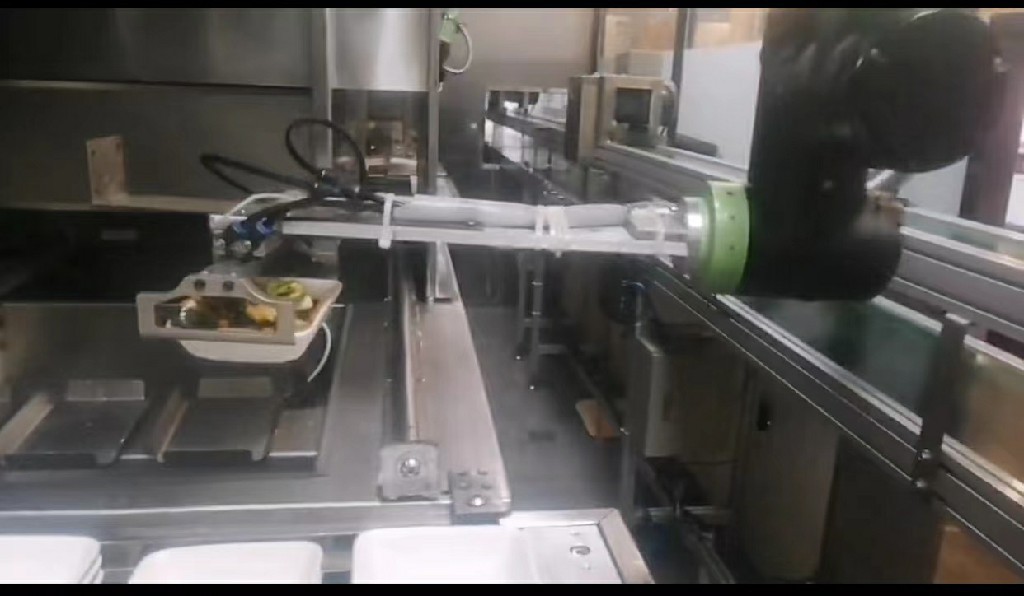

1. Robotic arms are widely used in the food and beverage industry, and the following are some specific application scenarios:

- Packing and loading: The robotic arm can be used for the packaging and loading of food and beverages, such as automatic packaging machines, automatic case packers, etc., thereby improving packaging efficiency and accuracy.

- Sorting and inspection: The robotic arm can be used for the sorting and inspection of food and beverages, such as automatic sorters, automatic inspection machines, etc., so as to improve product quality and hygiene.

- Handling and stacking: Robotic arms can be used for the handling and stacking of food and beverages, such as automatic handling machines, automatic stackers, etc., thereby improving production efficiency and reducing labor costs.

- Processing and manufacturing: Robotic arms can be used in the processing and manufacturing of food and beverages, such as automatic ovens, automatic filling machines, etc., thereby improving production efficiency and product quality.

2. Businesses can improve efficiency, hygiene and reduce costs by using robotic arms. Here are some specific ways to do it:

- Automated production line: Enterprises can integrate robotic arms into automated production lines, thereby improving production efficiency and accuracy while reducing labor costs and human errors.

- Optimize production processes: Robotic arms can help companies optimize production processes, such as reducing waiting times, improving product quality, etc., thereby increasing production efficiency and hygiene.

- Reduce operating costs: Robotic arms can reduce the operating costs of enterprises, such as reducing labor costs, reducing energy consumption, etc., thereby improving the profitability of enterprises.

- Improve product quality: Robotic arms can improve the quality and hygiene of food and beverage products, such as reducing cross-contamination, improving packaging accuracy, etc., thereby increasing the brand value and market share of enterprises.

In short, the application of robotic arms in the food and beverage industry can help enterprises improve production efficiency, hygiene level and product quality, thereby improving the profitability and market competitiveness of enterprises.