In the automotive industry, industrial robotic arms can improve production line efficiency by:

1) Accelerated parts assembly: The robotic arm can assemble parts into the car at high speed and accurately, which can greatly improve production efficiency and shorten the manufacturing cycle.

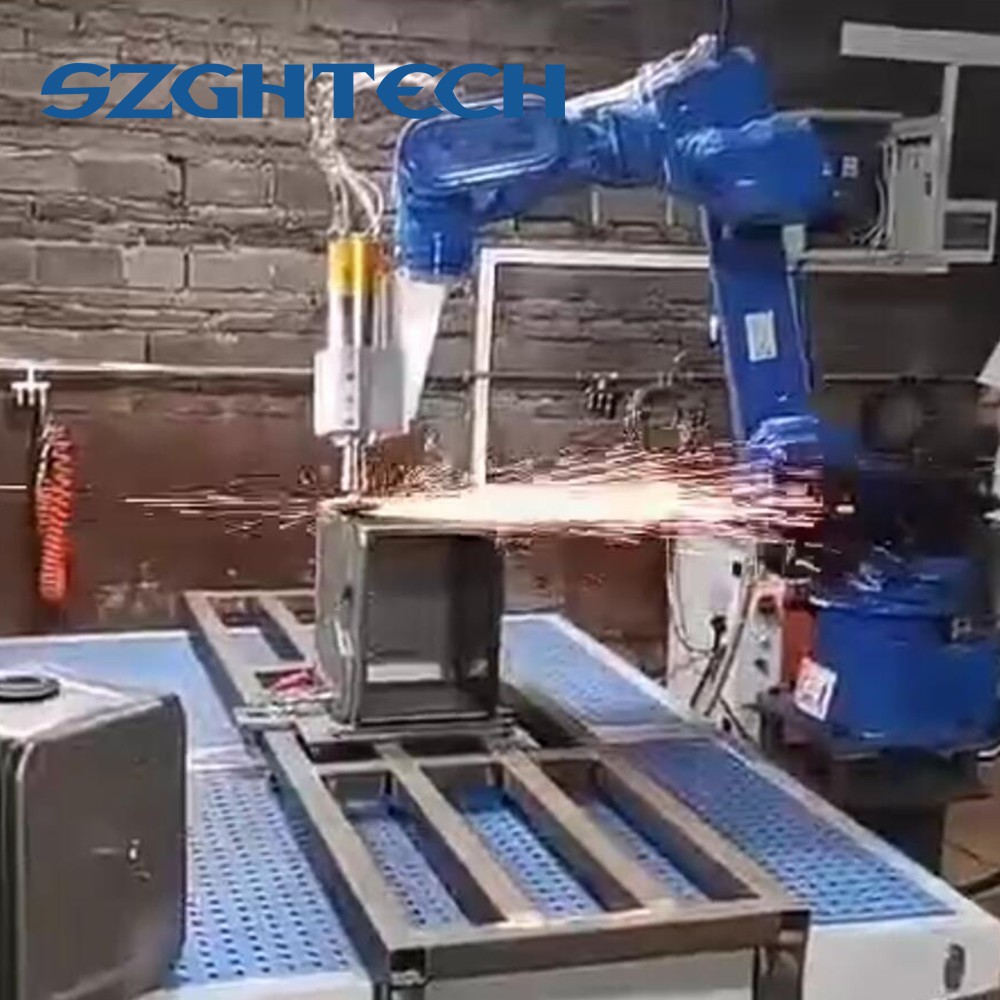

2) Improve welding efficiency: The robotic arm can automatically complete the welding work, which can not only improve the welding quality, but also greatly shorten the welding time and improve the welding efficiency.

3) Automatic spraying: The robotic arm can automatically spray automotive surface coatings, which can not only improve the spraying efficiency, but also improve the quality of the coating, avoiding some inevitable defects in manual spraying.

4) Cargo handling: The robotic arm can automatically move the goods in the assembly process of the car, which greatly improves the handling efficiency and reduces the human error in the handling process.

5) Intelligent detection: The robotic arm can be equipped with various sensors and imaging equipment to intelligently detect the car, thereby avoiding the manufacture of defective cars and improving production efficiency and product quality.

Through the above aspects, industrial robotic arms can improve the efficiency of the production line in the automobile manufacturing industry, and at the same time, it can also reduce human error and improve product quality, thereby further reducing costs and improving the profitability of automobile manufacturers.