To optimize the structure of a robotic arm, the following steps can be taken to improve production efficiency and reduce costs:

1) Analyze the production requirements: The first step in optimizing the structure of a robotic arm is to analyze the production requirements. This includes identifying the tasks that the robotic arm needs to perform, the speed and accuracy required, and the payload capacity.

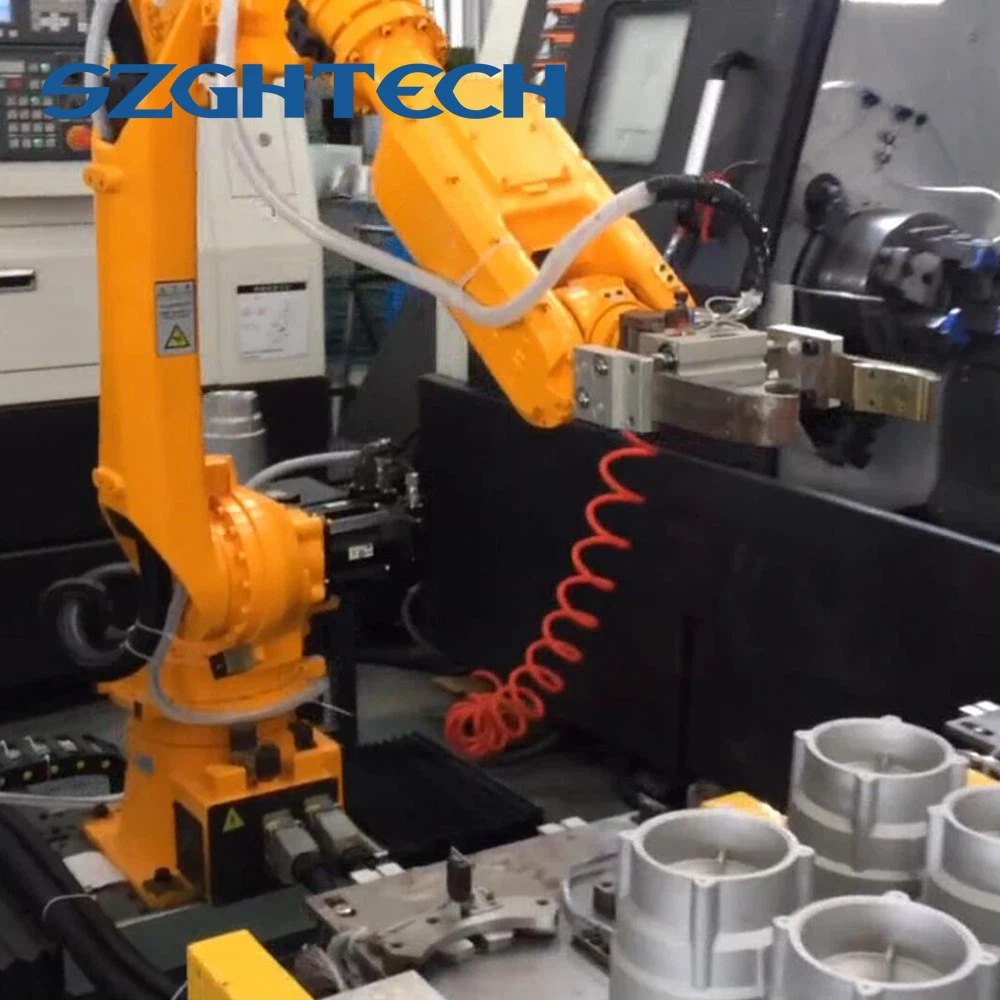

2) Select the appropriate arm structure: Once the production requirements are identified, the appropriate arm structure can be selected. This includes considering factors such as the number of axes, the range of motion, and the payload capacity.

3) Choose the right materials: The materials used to construct the robotic arm can have a significant impact on its performance and cost. Choosing lightweight materials can reduce the weight of the robotic arm, making it faster and more energy-efficient. At the same time, the materials should be strong and durable to ensure the robotic arm can withstand the stresses of industrial use.

4) Optimize the design: The design of the robotic arm can also impact its performance and cost. This includes optimizing the shape and size of the arm, minimizing the number of components, and reducing the number of joints to increase accuracy.

5) Implement advanced control systems: Advanced control systems, such as predictive maintenance and machine learning algorithms, can be implemented to optimize the performance of the robotic arm. This includes real-time monitoring of the arm's performance, predicting maintenance needs, and adjusting the arm's parameters to optimize its performance.

6) Consider modularity: Modularity refers to the ability to easily replace or upgrade components of the robotic arm. A modular design can make it easier and more cost-effective to maintain and repair the robotic arm, reducing downtime and improving production efficiency.

7) Conduct testing and analysis: Once the optimized structure is designed and implemented, testing and analysis should be conducted to evaluate the performance of the robotic arm. This includes testing its accuracy, speed, and energy efficiency, as well as identifying any potential issues and addressing them before they become major problems.

By following these steps, the structure of a robotic arm can be optimized to improve production efficiency and reduce costs, ultimately resulting in significant cost savings for manufacturers.