-

Precision Control And Lifting Method Of Lathe Processing2023-07-10 11:03:32The precision control and improvement of lathe processing is an important aspect to ensure the processing quality and dimensional accuracy of parts. The following are some commonly used methods and techniques to control and improve the accuracy of lathe processing: Machine tool selection: Choosing a machine tool with high precision and good stability is the key to ensuring machining accuracy. Consider factors such as the rigidity, precision, guide rail type, and spindle accuracy of the machine tool, and ensure that it meets the machining requirements.

-

Application Of Robot Arm In Logistics And Warehousing2023-07-06 18:22:47Robotic arms are becoming more common in logistics and warehousing, increasing efficiency, reducing costs, and bringing many advantages to logistics and warehousing operations. Here are some of the applications of robotic arms in logistics and warehousing: 1. Handling and handling: Robotic arms can be used to handle and load and unload goods, including removing goods from shelves, placing goods in place, and loading goods onto means of transport. This reduces manual labor and increases the efficiency and accuracy of logistics.

-

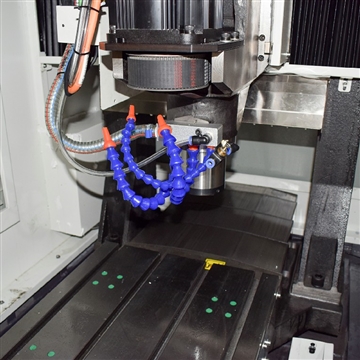

Milling Machine Tool Selection And Maintenance Method2023-06-29 18:39:55Milling Machine Tool Selection: When selecting milling machine tools, it's important to consider the specific machining requirements, the type of material being machined, and the desired outcome. Here are some factors to consider during tool selection:

-

The Working Principle And Processing Method Of The Milling Machine2023-06-29 18:33:36The working principle of a milling machine involves the removal of material from a workpiece using rotary cutters. The machine consists of a stationary workpiece, called the worktable, and a rotating cutting tool, known as the milling cutter. As the milling cutter rotates, it moves along multiple axes to cut into the workpiece and remove material.

-

Lathe Operation Tips And Safety Precautions2023-06-27 18:34:56When operating a lathe, it is essential to follow certain tips and safety precautions to ensure a safe and efficient working environment. Here are some guidelines to consider:1. Familiarize Yourself with the Machine,2. Wear Proper Attire,3. Secure the Workpiece,4. Choose the Right Cutting Tools,5. Set Correct Speeds and Feeds,6. Take Light and Gradual Cuts,7. Monitor the Cutting Process,8. Perform Regular Maintenance.

-

Types And Scope Of Application Of Lathes2023-06-27 18:29:42Lathes are versatile machine tools used for various machining operations, primarily involving the rotation of a workpiece. Different types of lathes are designed to cater to specific applications. Here are some common types of lathes along with their scope of applications: 1. Engine Lathe: Engine lathes, also known as center lathes, are the most common type of lathe. They are suitable for a wide range of applications, including: - Turning operations: Creating cylindrical shapes, such as shafts, rods, and discs. - Facing operations: Cutting flat surfaces perpendicular to the axis of rotation. - Taper turning: Producing tapered shapes, such as conical parts or threads. - Drilling and boring: Performing drilling and hole enlargement operations. - Threading: Cutting external or internal threads.

-

The Role Of Robotic Arms In Production Automation2023-06-27 18:19:31Robotic arms play a crucial role in production automation by performing a wide range of tasks with speed, precision, and consistency. Here are some key roles that robotic arms fulfill in production automation: 1. Pick and Place: Robotic arms excel at picking up objects from one location and placing them in another. They can handle a variety of shapes, sizes, and weights, making them ideal for repetitive and precise picking and placing tasks in assembly lines or warehouses.

-

What Are The Classifications And Characteristics Of Robotic Arms?2023-06-27 15:54:15Robot arms can be classified into different types based on their structure and characteristics. Here are some common classifications of robot arms along with their characteristics: 1. Cartesian Robot: - Structure: Consists of three perpendicular linear joints, resembling a Cartesian coordinate system. - Characteristics: Simple structure, precise movement along X, Y, and Z axes, good for pick-and-place operations and linear movements.

-

How to choose the right CNC system configuration?2023-06-27 12:11:02Choosing the right CNC system configuration needs to consider the following factors: 1. Processing needs: First of all, it is necessary to clarify what your processing needs are. Is it a simple 2D machining or a complex 3D machining required? Need to cut at high speed or precision engraving? Understanding your machining needs will help determine the required CNC system configuration.

-

The basic working principle and application field of CNC system2023-06-27 12:02:46A computer numerical control (CNC) system is a technology that uses computers to control the movement of tools or machines. It controls the movement of the machine or tool through pre-programmed instructions to achieve high-precision, high-efficiency machining operations. The following is an introduction to the basic working principle and application areas of CNC systems:

-

Understanding The High-Precision Machining Capabilities Of Lathe Machines, How To Meet The Challenges Of Precision Parts Manufacturing?2023-06-09 19:42:46Meeting the challenges of precision parts manufacturing requires careful consideration of various factors when using lathe machines. Here are some strategies to ensure high-precision machining: 1. Machine Selection: Choose a lathe machine that is specifically designed for high-precision machining. Look for features such as high rigidity, vibration damping, and thermal stability. A machine with high-precision components, such as precision ball screws and linear guides, can contribute to maintaining accuracy during machining. 2. Tooling Selection: Select cutting tools that are specifically designed for high-precision machining. Consider factors such as tool geometry, cutting-edge sharpness, and tool material. High-quality carbide or ceramic tools with sharp cutting edges are often preferred for precision machining. Use tools with the appropriate coatings to reduce friction and improve tool life.

-

How Does The High-Speed Cutting Technology Of Lathe Machine Improve The Processing Efficiency?2023-06-09 19:32:57High-speed cutting technology in lathe machines offers several advantages that improve processing efficiency. Here are some ways in which high-speed cutting technology enhances efficiency: 1. Reduced Cycle Time: High-speed cutting allows for faster cutting speeds and higher feed rates compared to conventional machining. This reduces the time required to complete each machining operation, resulting in shorter cycle times. Shorter cycle times translate to increased productivity and higher throughput. 2. Increased Material Removal Rate: High-speed cutting enables higher depths of cut and larger chip loads while maintaining stable cutting conditions. This leads to a significant increase in material removal rate, allowing more material to be removed in a shorter period. It results in faster machining and improved efficiency.