Before weaving the program, firstly choose a reasonable welding smoothness, the purpose is to reduce the welding deformation, so the welding sequence can be formulated according to the length of the welding torch walking path. For the space transition of the welding torch, the most basic requirements are short, smooth and safe moving trajectory; on this basis, the welding parameters are optimized. In order to obtain the best welding parameters, the welding test and process evaluation can be carried out by making working samples.

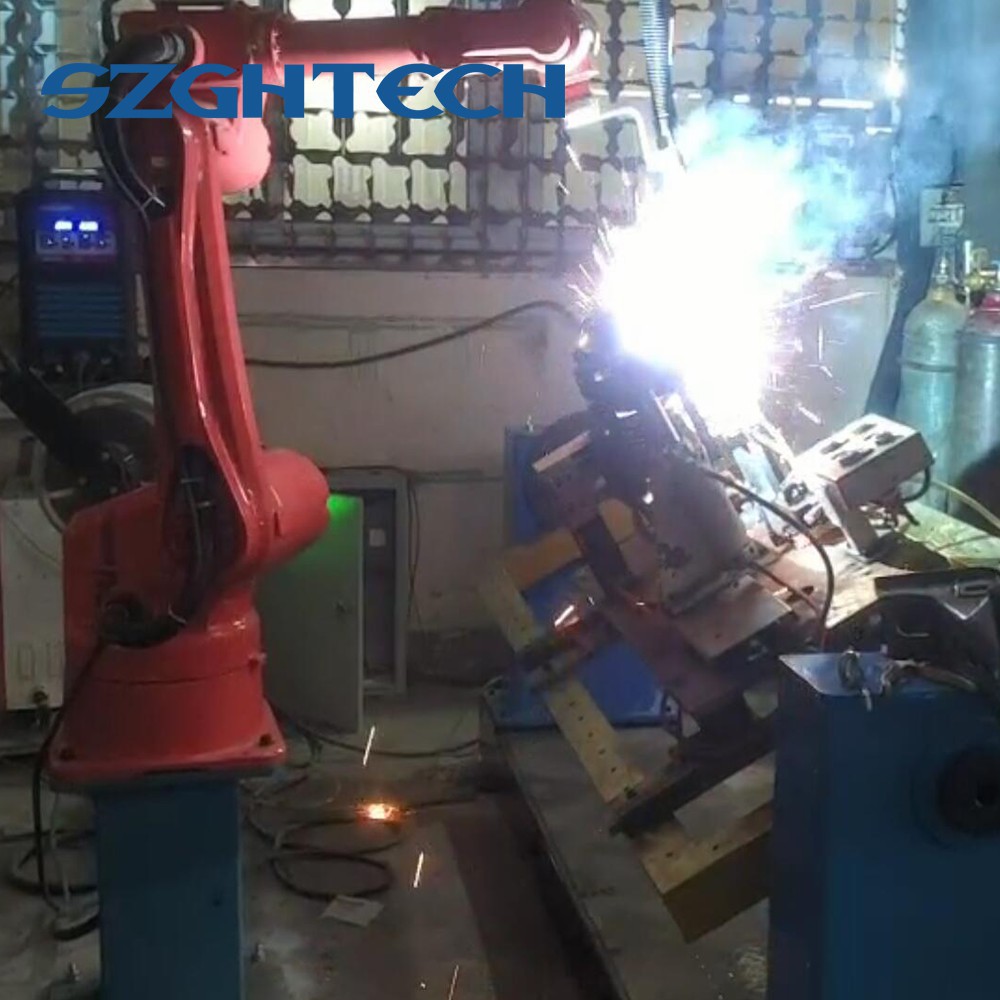

Since the welding robot was successfully developed, it has also been widely used in practice, and the reason why it can accurately complete various complicated welding processes depends entirely on the programming of corresponding programs.

Secondly, considering that the position of the positioner, the posture of the welding torch, and the position of the welding torch relative to the joint match the welding requirements, it is required to continuously adjust the positioner during programming, so that the welded seam reaches the horizontal position one by one according to the welding sequence. At the same time, it is necessary to constantly adjust the position of each axis of the robot, and reasonably determine the position and angle of the welding torch relative to the joint and the length of the welding wire.

After a certain length of welding program is written, the torch cleaning program should be inserted in time, which can prevent welding spatter from blocking the welding nozzle and contact tip, help to ensure the cleaning of the welding torch and improve the life of the nozzle. In short, the programming of the operation program of the welding robot generally cannot be completed in one step, and it must be continuously inspected, modified and adjusted during the robot welding process.