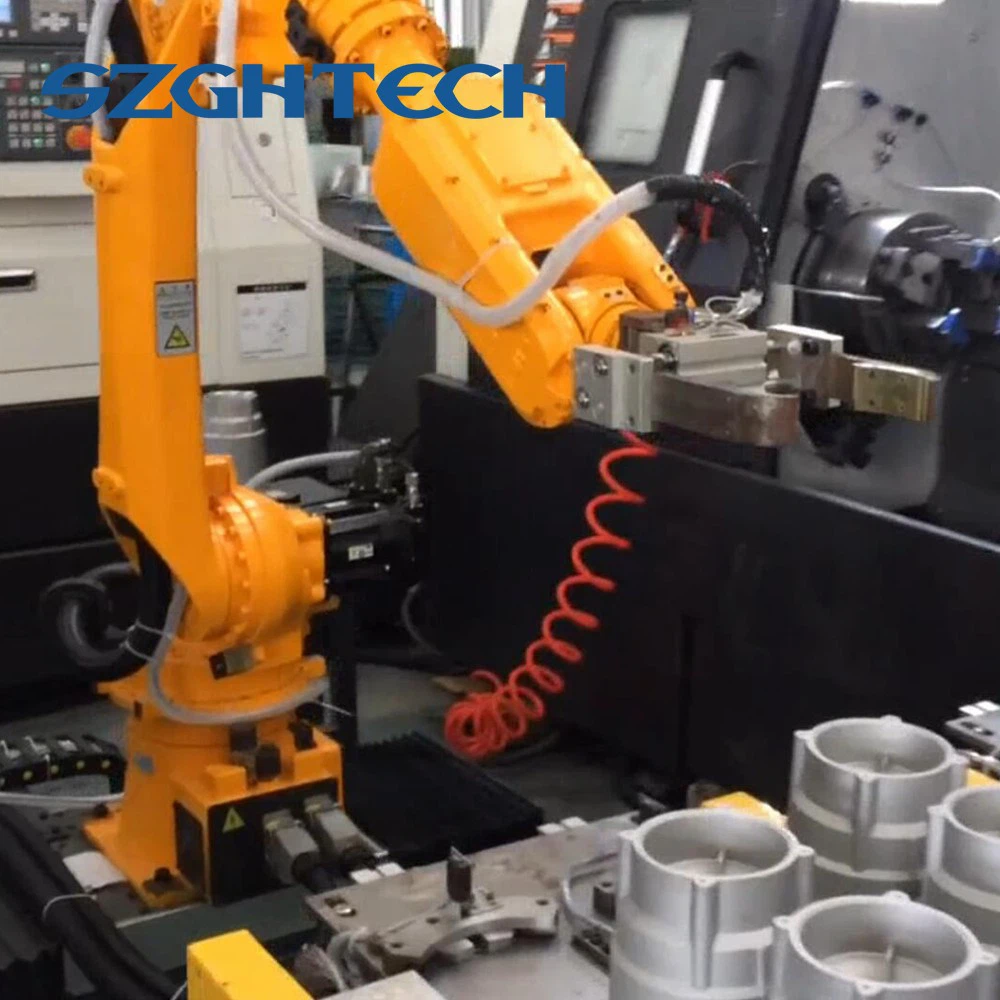

Industrial robotic arms have a wide range of applications in semiconductor manufacturing, including the following:

1) Wafer handling: The robotic arm can perform wafer handling, loading and unloading, flipping, positioning and other operations during the semiconductor manufacturing process. Wafers are key components in the semiconductor manufacturing process and need to be processed in a high-cleanliness environment, and the robotic arm can ensure the safe and accurate processing of wafers through its high-precision and high-stability motion control, thereby improving the quality and efficiency of the manufacturing process.

2) Process-assisted operations: The robotic arm can perform some auxiliary operations in the semiconductor manufacturing process, such as pasting, cleaning, coating, etc. These operations require highly accurate motion control and positioning, and robotic arms can provide reliable process assistance functions through their highly flexible means and high-precision operation.

3) Test and inspection: Robotic arms can perform chip testing and inspection tasks during semiconductor manufacturing. Through the high-speed, high-precision movement and flexible means of the robotic arm, the automatic testing and inspection of chips can be realized, and the efficiency and accuracy of testing and inspection can be improved.

4) Material management: Robotic arms can perform material handling, storage, and management tasks during semiconductor manufacturing. In the semiconductor manufacturing process, a large number of materials need to be managed, including wafers, chips, masks, thin films, chemical reagents, etc., and the robotic arm can realize the automatic management and processing of materials through its efficient material handling capabilities and flexible means.

5) Environmental control: The robotic arm can perform some environmental control tasks in the semiconductor manufacturing process, such as cleaning, drying, atmosphere control, etc. These tasks require highly accurate motion control and environmental control, and the robotic arm can automate environmental control through its high-precision motion control and flexible means.

In summary, industrial robotic arms are widely used in semiconductor manufacturing, and through their high precision, high stability and high efficiency, they can improve the quality, efficiency and automation of the semiconductor manufacturing process.