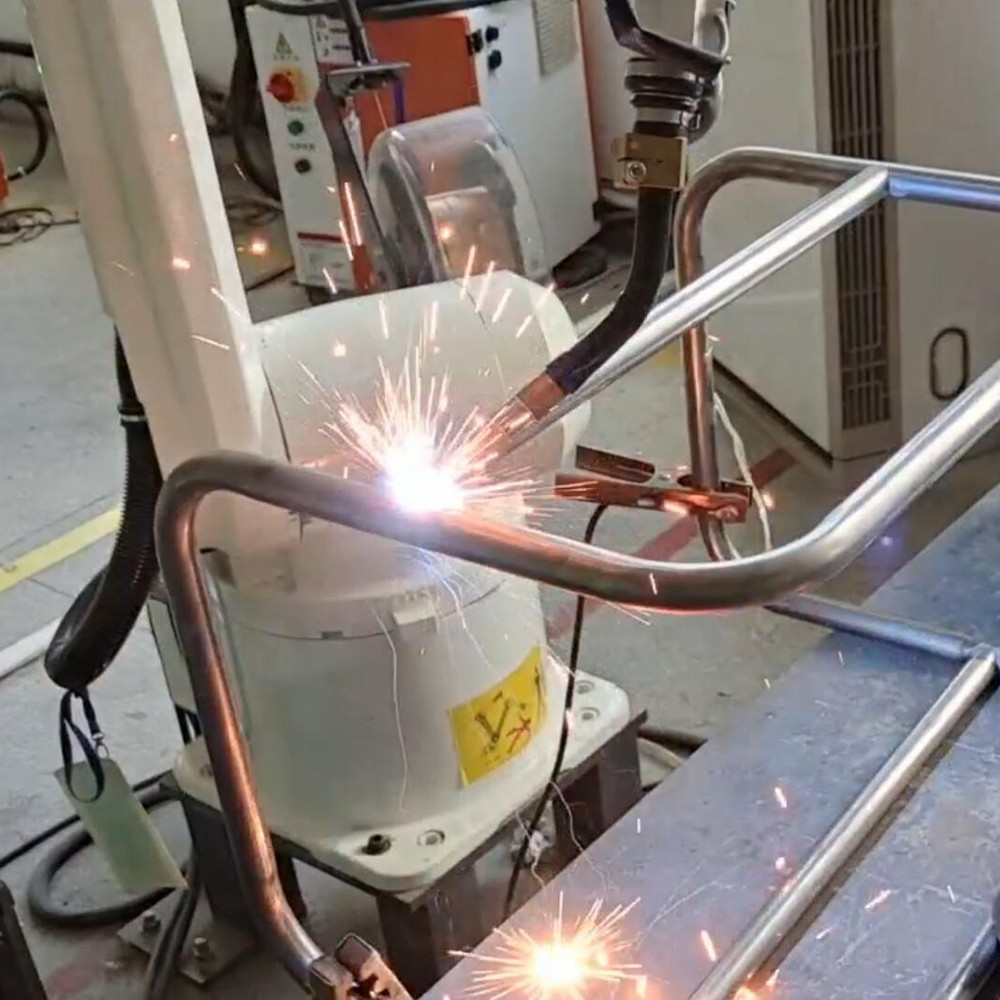

The robot moves smoothly, the end speed is consistent with the set welding speed, the welding is stable and the forming is good;

The robot and the welding machine realize full digital communication control, which can exert the best welding efficiency and welding effect;

It is possible to set welding parameters on the robot, or for the same workpiece to have different plate thicknesses and require different welding process conditions: parameters such as duty cycle, frequency, etc., can also be achieved by calling different job numbers by the robot.

500A water-cooled hollow supports long-term double-pulse welding;

Single/Dual Pulse Digital Welder

Constant penetration, when the dry elongation changes, it still maintains a stable current output;

Smooth short-circuit transition, uniform weld bead, and beautiful shape;

Short arc technology, faster welding speed;

High-frequency pulsation energy control, deeper penetration, more beautiful fish scales; low heat input;

Wire feeding with encoder feedback is more stable and anti-interference is strong;

Upgradable expert database;

The push-pull welding torch interface controls the push-pull welding torch, which makes the wire feeding more stable and the arc fluctuation is small;

Scope of application:

2.5mm--14.0mm aluminum or aluminum alloy welding

Application areas:

Aluminum alloy bicycles, aluminum film panels, aluminum fans, aluminum auto parts, aluminum alloy scaffolding and other industries