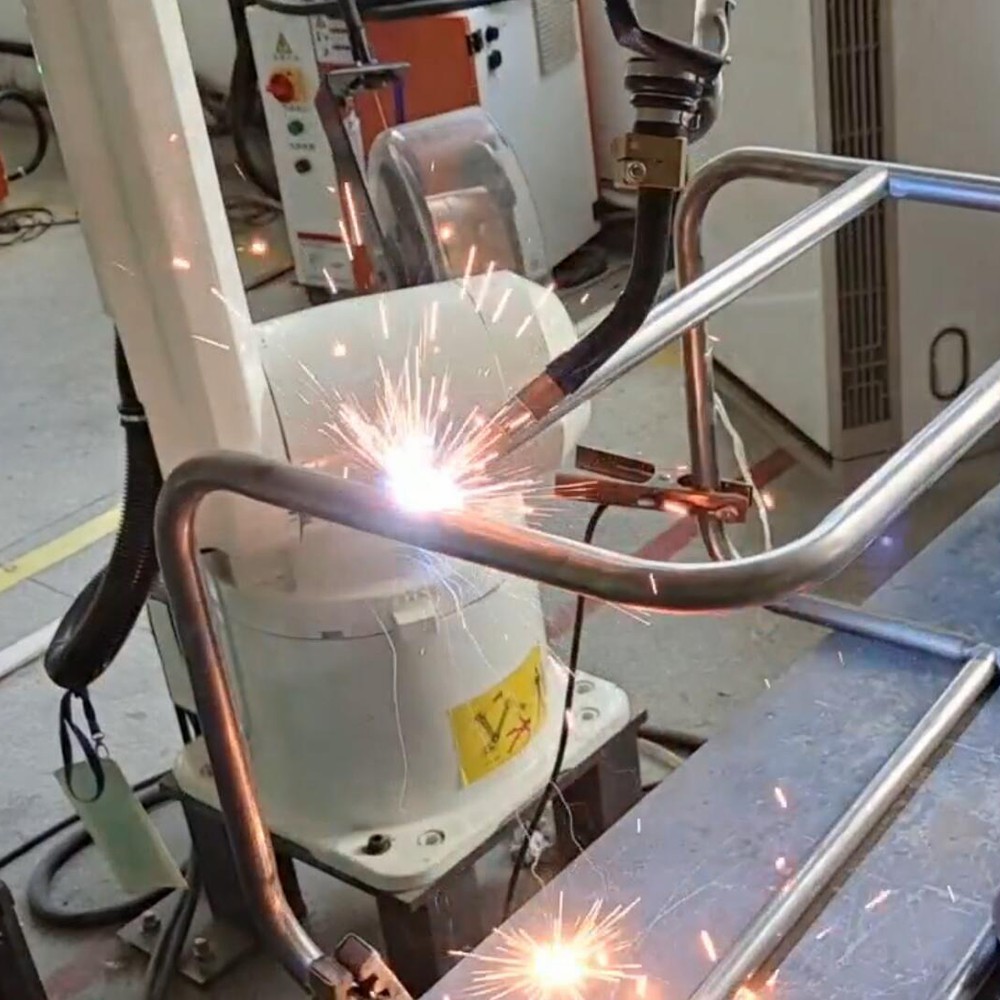

TIG self-melting technology features:

The robot moves smoothly, the end speed is consistent with the set welding speed, the welding is stable and the forming is good;

A high-frequency isolation accessory package is installed to avoid high-frequency damage to the robot under normal installation conditions;

The welding machine can choose DC and DC pulse mode;

The current is given by the robot, and the parameter changes are easily realized.

Easy arc ignition

The arc is stable and the molten pool is easy to control. The water-cooled welding torch with angle adjustment, the water pipe and the welding cable are separated, and the long-term use will not damage the TIG wire filling. Technical features:

The robot moves smoothly, the end speed is consistent with the set welding speed, the welding is stable and the forming is good;

A high-frequency isolation accessory package is installed to avoid high-frequency damage to the robot under normal installation conditions;

The welding machine can choose DC/DC pulse, AC/AC pulse mode;

The current and wire feeding speed are given by the robot, and the parameters can be changed conveniently. Various parameters can be set to preheat and prevent wire sticking.

Intermittent wire feed synchronized with pulses is possible.

Stable arc and easy control of molten pool.

Easy arc ignition.

Water-cooled welding torch with angle adjustment, separate water pipe and welding cable, no damage after long-term use.

The angle of the wire feed bracket is easily adjustable.

Scope of application:

Self-melting for carbon steel above 0.8mm and stainless steel above 1.2mm for aluminum and non-ferrous metals

Filling wire is more than 1.0mm carbon steel and stainless steel more than 1.5mm aluminum and non-ferrous metals.