There is no advantage in the price of domestic robots. In the past 10 years, the price of imported robots has been greatly reduced, from US$70,000 to US$80,000 to US$20,000 to US$30,000, making it difficult for ordinary industrial robots manufactured by my country to compete with them in terms of price, especially in the initial stage of the development of robots in my country, there is no simultaneous development of the corresponding parts industry, such as servo motors, reducers, etc., which need to be imported, making it difficult to reduce the price, so the production cost of robots cannot be reduced; There is a big gap, which indirectly affects the development of domestic robots. For the big users of robots --- automobile body-in-white manufacturers, almost all the equipment is imported from abroad at present, and there is almost no stage for domestic robots to perform.

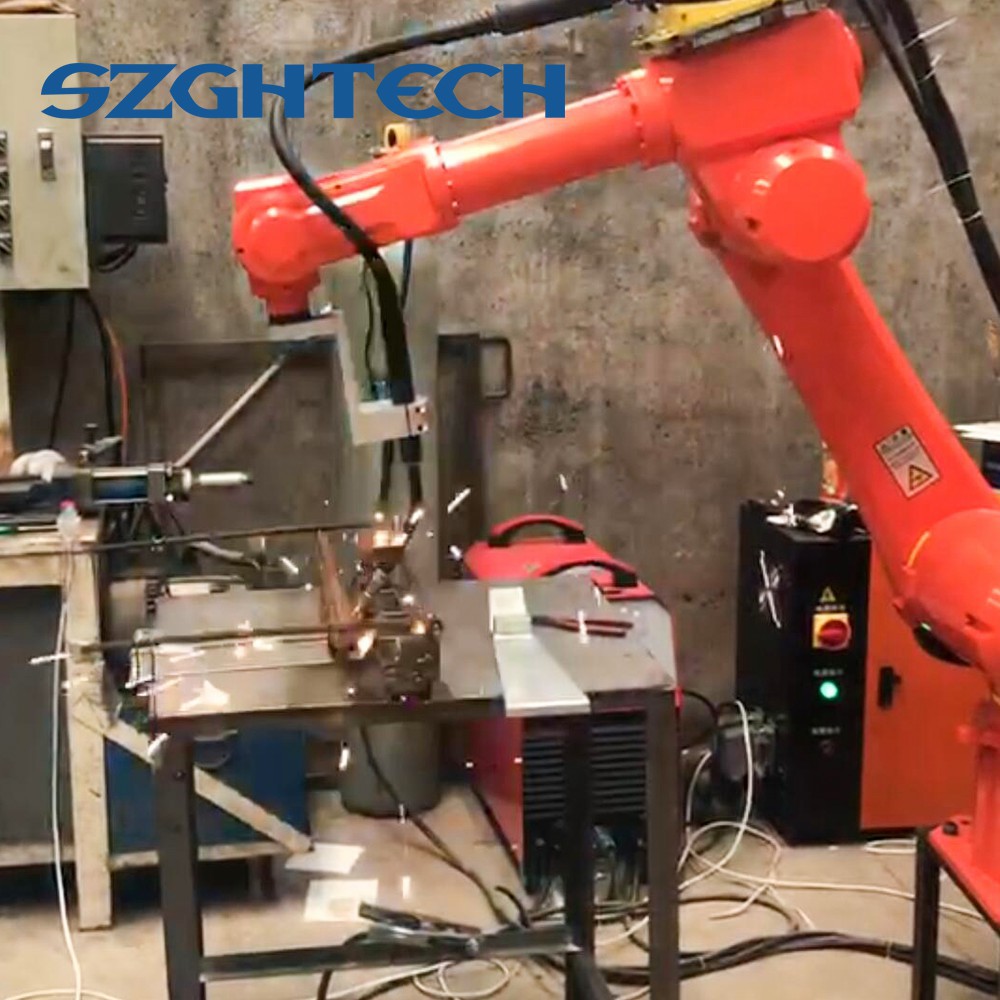

At present, the robots used in my country are mainly divided into three types: Japanese, European and domestic. Domestic robots are mainly products of SZGH Robot Company. The Japanese products mainly include Yaskawa, OTC, Panasonic, FANUC, Fujikoshi, Kawasaki and other companies. The European series mainly include KUKA and CLOOS from Germany, ABB from Sweden, COMAU from Italy and IGM from Austria.

At present, although our country already has a series of welding robot products with independent intellectual property rights, it cannot be mass-produced and scaled up. There are several main reasons:

We should admit that there is still a certain gap between domestic robots and foreign companies in terms of control level and reliability. Foreign industrial robot is a very mature industrial product, which has experienced more than 30 years of development, and has been continuously improved and improved in actual production, while our country is in a state of single-piece and small-batch production.

Domestic robot manufacturers are still in their infancy and still need the support of government policies and funds. Welding robot is a high-tech product of mechatronics. It is not enough to rely on the company's own capabilities. It is necessary for the government to provide certain policy and financial support to robot manufacturers and companies using domestic robot systems to accelerate the development of domestic robots in China.

In welded parts with relatively simple processes, Chinese-made welding robots have a strong competitive advantage. Moreover, the structure is simple, the requirements for employee skills are relatively low, and the repair cost is relatively low.

Among imported welding robots, complex workpiece welding can be realized, and there are strong skill requirements for operators and repairers. The accessories are relatively expensive, and it is difficult to supply them in time.

What Are The Differences Between Domestic Welding Robots And Imported Welding Robots?

2022-12-23 10:10:39 View: 891

Previous

No InformationNext

No InformationSend Inquiry