Hot selling SZGH 7 axis manipulator robot arm with CE certificate Brand new 12 month Garantee Period welding robot arm

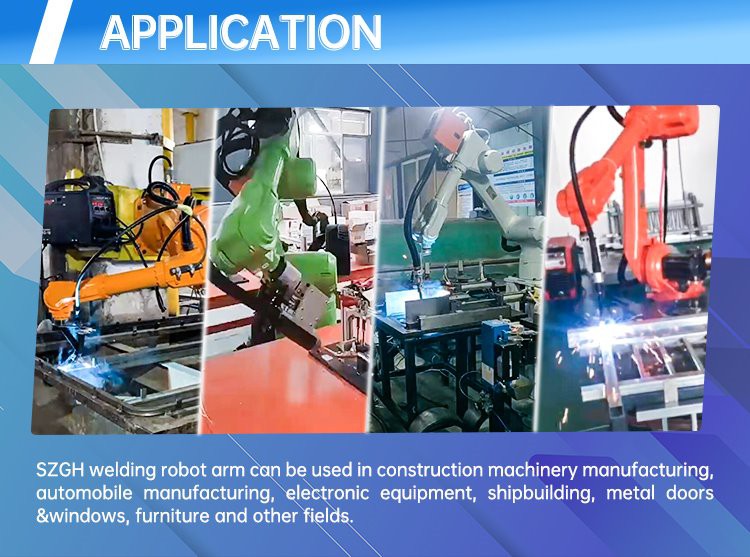

SZGH-H1500-B-6 robot is dedicated to welding; easy operation, high efficiency and safety.

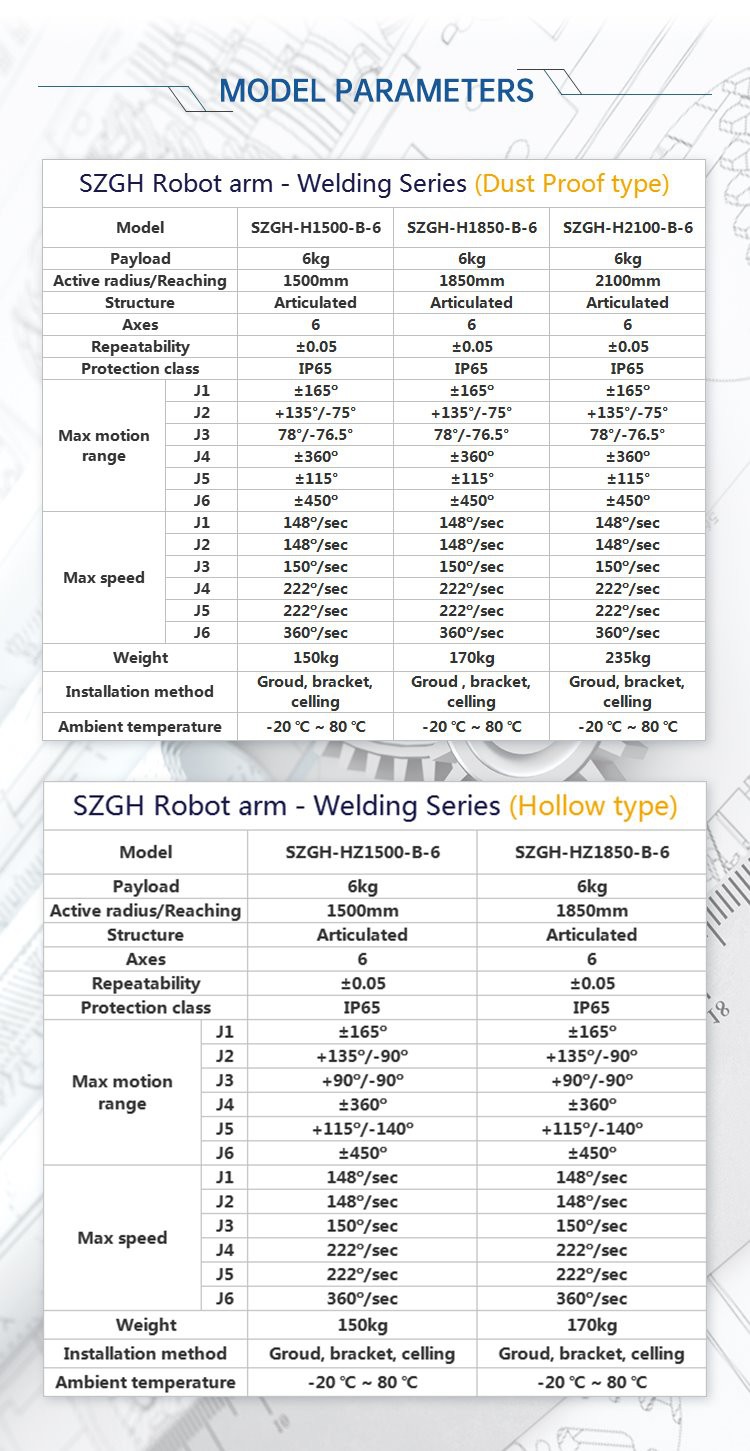

Model | SZGH-H1500-B-7 |

| Payload | 6kg |

Reach | 1500mm |

Axes | 6-11 Axes |

Application | welding |

Special Service | 1. We can customize the standard color as you need! |

After Warran | Video technical supports , Online supports |

1) Support up to 12axis control, realizes the control of external axes(traveling axes and positioner).

2) Suitable for multiple increments; absolute servo.

3) Modular setting of functionssuitable for diverse applications. 8-axis control realizes the control of external axes (traveling axes and positioner).

Q1: What is the delivery time?

A3: It would be 3~5 working days for the standard machine; it would be 7 ~10 working days for the customized machine.

Q2: How to guarantee the quality of your products?

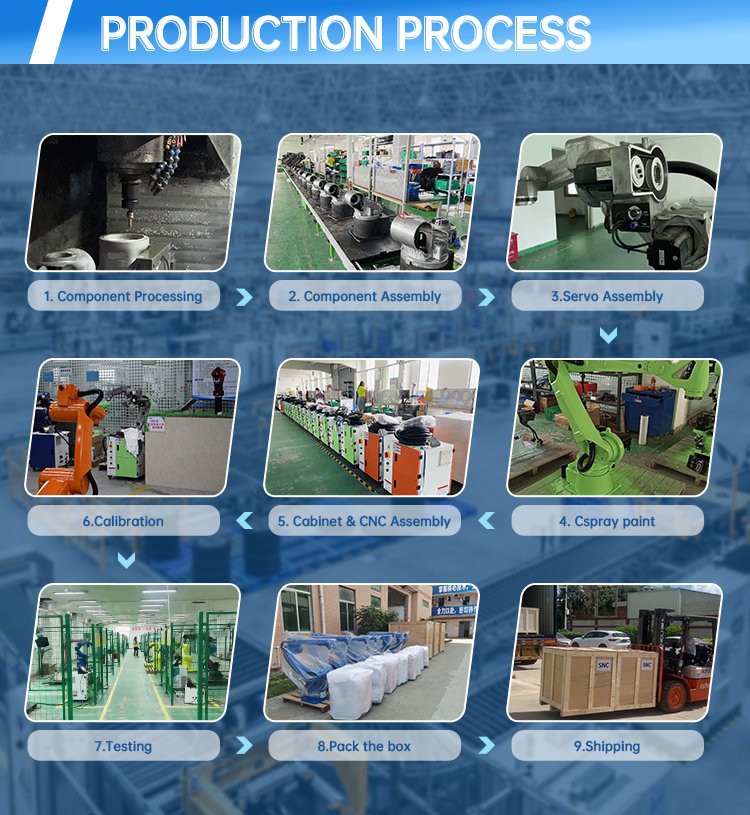

A4: The whole production procedure will be under regular inspection and strict quality control. The machine will be tested to make sure they can work very well before being out of factory.

Q3: Can you teach us how to use the machine?

A2: Yes, we will send you guiding vedio. If you still don't konw how to use it, we can talk by phone, email or other social media software.

If you have any questions, pls feel free to contact me below.