On the premise of ensuring quality, the diversification of products and the fashionable style make our 80 86mm Flange Ac Servo Motor, 37kw ac servo spindle motor, 6 axis robot arm for camera sell well at home and abroad, and have won the trust and high praise of our customers. We do our job strictly according to the requirements with due diligence, pay attention to feedback and communication, and form an up-and-down coordination and linkage and flexible adjustment of the operation mechanism. Our company with professional technical services and strong technical strength, to provide customers with quality service. We adhere to the principle of 'positive enterprising and innovative thinking', constantly explore and innovate, take service as the core, regard customers as God, and wholeheartedly provide you with perfect solutions and meticulous service.

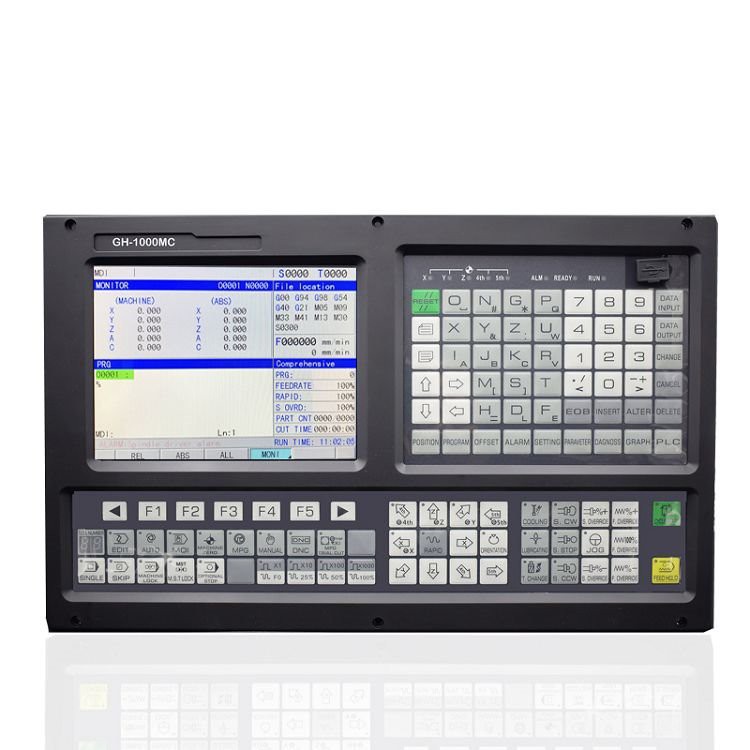

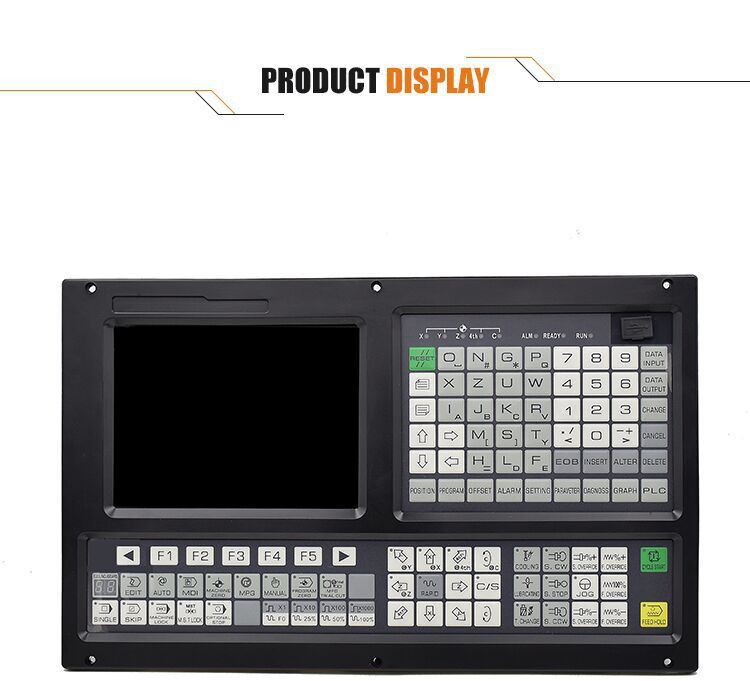

As siemens milling controller Support PLC ATC 3 Axis Milling CNC Machine Control system with USB

Number of control axes | 3axes (X,Y, Z) |

Minimum programming | 0.001mm |

Maximum programming | ± 99999.999mm |

Top speed | 30m / min |

Feed speed | 0.001-15m / min |

Manual continuous | One axis or simultaneous multi-axis |

Interpolation method | Straight line, arc, thread interpolation |

Tool offset | Length compensation, nose radius C compensation |

Spindle functions | Gear, dual analog control, rigid tapping |

Handwheel functions | Panel type, plug-in hand-held |

Screen saver function | Screen saver function |

Communication function | RS232, U disk interface |

Compensation function | Knife compensation, between compensation, screw compensation, radius compensation |

Program editing | Male / English, relative / absolute programming |

Limit function | Software limit, hardware limit |

Pre-reading function | Short line preprocessing 10,000 lines |

Password protection | Multi-level password protection |

Input and output | I / O point 24X24 |

PLC programming | The user is free to design PLC function |

Acceleration and deceleration control | Linear acceleration and deceleration, the number of additions and subtractions |

Encoder lines | Any setting |

User macro program | Yes |

Electronic gear functions | Yes |

Number of control axes | 3axes (X, Y, Z) |

Minimum programming | 0.001mm |

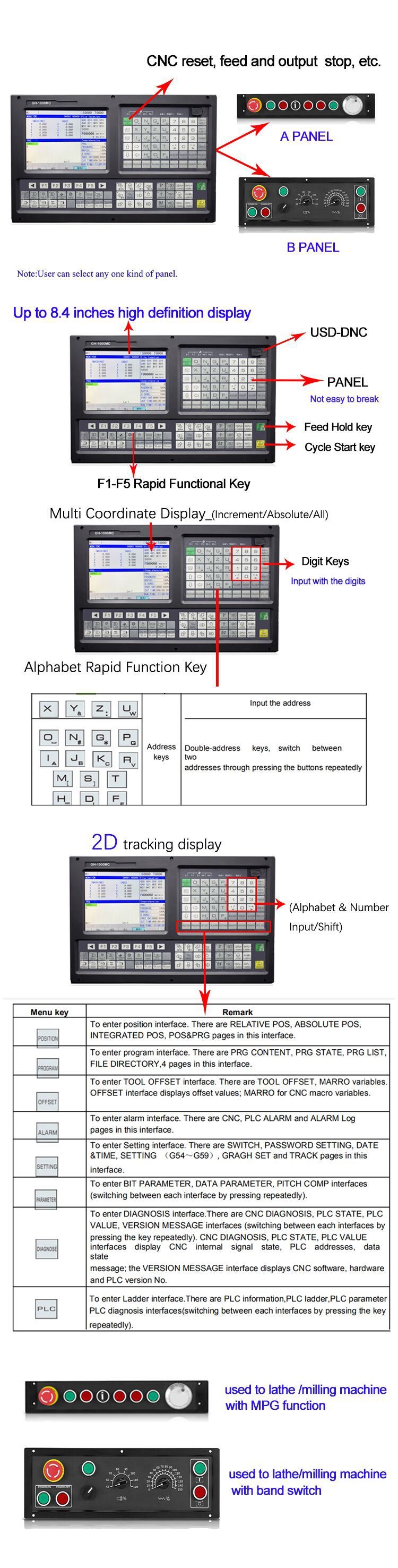

* Control axis: 3-5 axis (X, Y, Z,A,B)

* Interpolationaxis: Any 3 axis linear interpolation , any 2 axis circular interpolation

Spindle axis functions:

* Two channels 0V ~ 10V analog voltage output, support double spindle control

* Spindle encoder: encoder lines can be set (100 p/r ~ 5000p/r)

* Encoder and spindle’s transmission ratio: (1 ~ 255):(1 ~ 255)

Tool functions:

* Tool length compensation

* Tool point radius compensation (C type)

Precision compensation:

* Thread pitch error compenstation: Compensation points, compensation interval, compensate original position can be set.

* Backlash compensation: can set reverse interval to interpolation machine tool by fixed frequency or lifting speed mode.

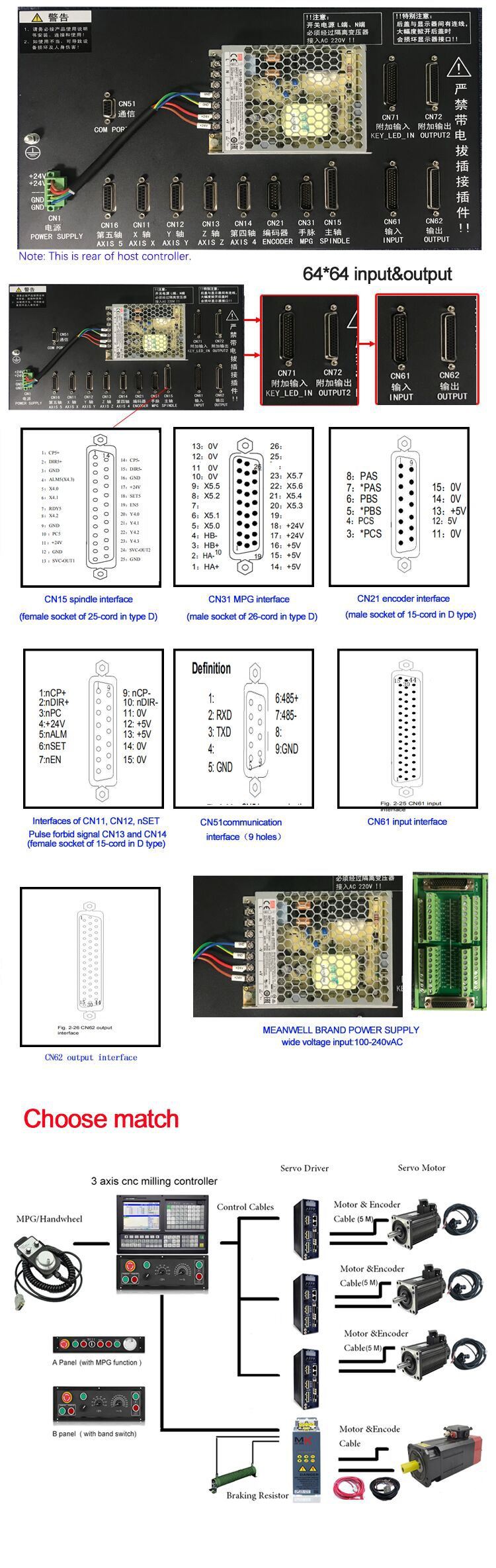

Related products:

2,Axis servo motor &driver

3.Spindle Servo Motor&driver

4,Rotary table

High quality products&Professional service

FAQ

Q: Which payment form you can accept?

A: T/T, Western Union, PayPal etc. We accept any convenient and swift payment term.

Q: Which certificate do you have?

A: CE and ER

Q: Do you have the test and audit service?

A: Yes, we can assist to get the designated test report for product and the designated factory audit report.

If you have another question, pls feel free to contact us as below

Our continuous investment in innovation provides a strong guarantee for the company to grasp consumer trends and lead the direction of 2 Axis CNC Controller for CNC Lathe or CNC Turning industry development. We take the plan management as the goal, resource integration as the basis, quality improvement as the core, market expansion as the focus, technological innovation as a breakthrough, and strive to achieve gold-medal quality. We plan carefully, try boldly, innovate constantly, and strive to give back to the society and manifest the positive energy of the enterprise.