Our product criterion is high quality and low price. Our servo spindle motor cnc, 6KG 1500mm Welding Robot Arm, 100 watt ac servo motor are the most cost-effective products among the same products. In the long-term development process, we have established long-term good partnerships with many large domestic and foreign manufacturers with excellent product quality, good product performance, and high-quality service system. We also sincerely welcome domestic and foreign customers to come to our company for inspection, visit and technical exchanges! We have always adhered to an unconventional and leap-forward sustainable development path, which has created the foundation for long-term development. Our company always adheres to the concept of technological innovation, owning economic and technical strength, and a high-quality management team.

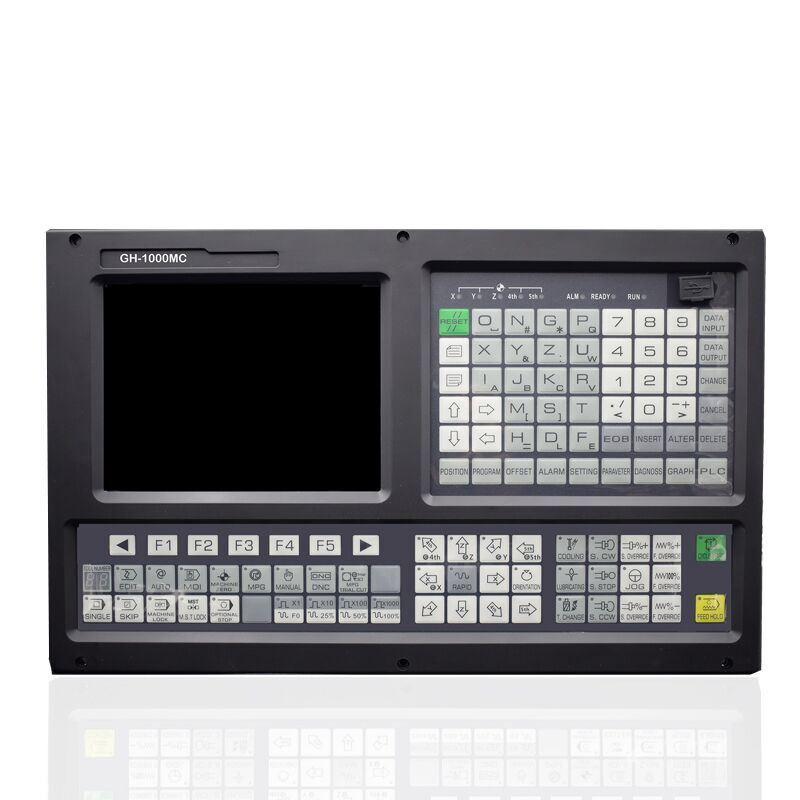

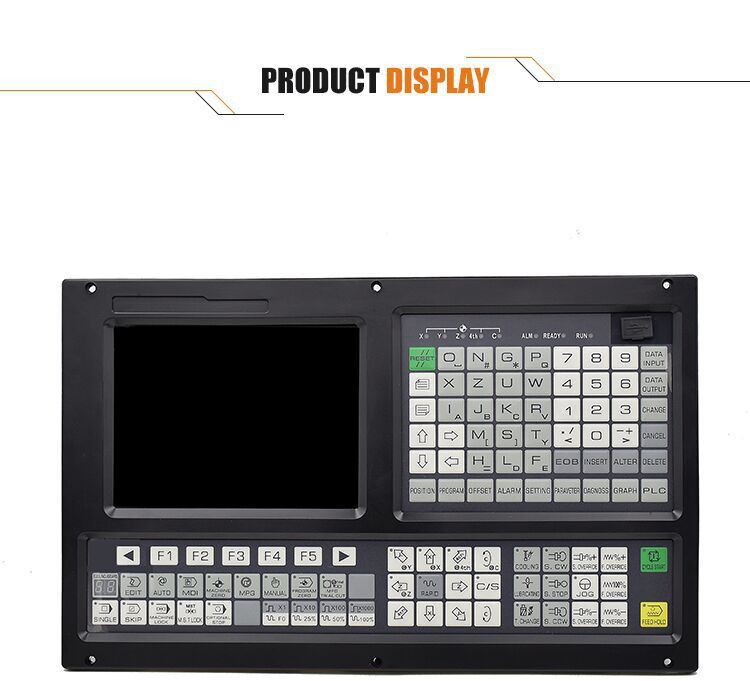

4 Axis Lathe and Turning CNC controller with new control panel ARM+DSP+FPGA usb cnc complete kit

Number of control axes | 4axes (X, Y, Z, A) |

Minimum programming | 0.001mm |

Maximum programming | ± 99999.999mm |

Top speed | 30m / min |

Feed speed | 0.001-15m / min |

Manual continuous | One axis or simultaneous multi-axis |

Interpolation method | Straight line, arc, thread interpolation |

Tool offset | Length compensation, nose radius C compensation |

Spindle functions | Gear, dual analog control, rigid tapping |

Handwheel functions | Panel type, plug-in hand-held |

Screen saver function | Screen saver function |

Communication function | RS232, U disk interface |

Compensation function | Knife compensation, between compensation, screw compensation, radius compensation |

Program editing | Male / English, relative / absolute programming |

Limit function | Software limit, hardware limit |

Pre-reading function | Short line preprocessing 10,000 lines |

Password protection | Multi-level password protection |

Input and output | I / O point 24X24 |

PLC programming | The user is free to design PLC function |

Acceleration and deceleration control | Linear acceleration and deceleration, the number of additions and subtractions |

Encoder lines | Any setting |

User macro program | Yes |

Electronic gear functions | Yes |

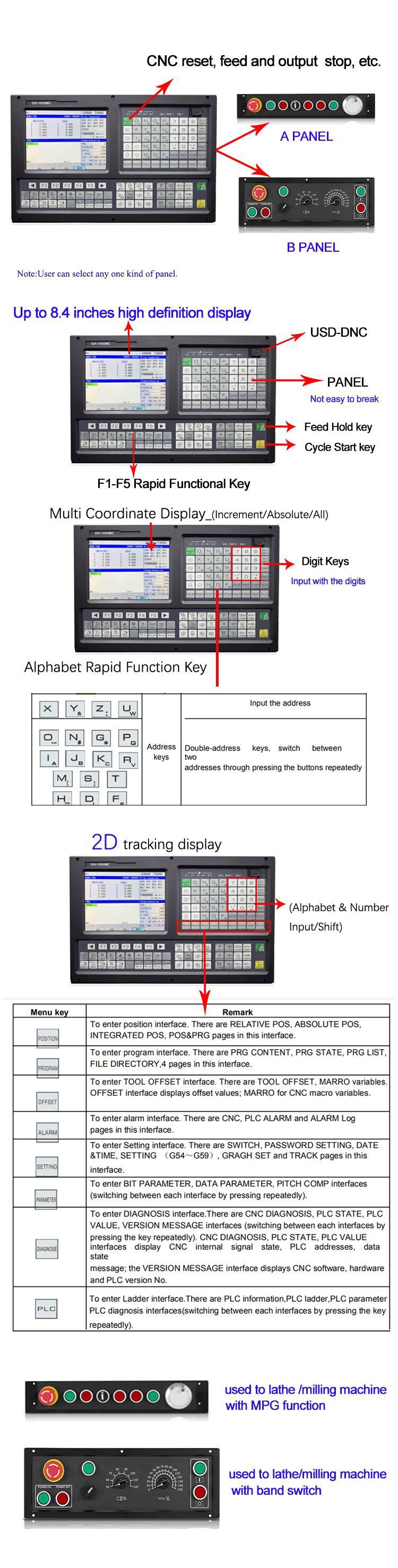

Vice-panel | A-type panel with hand wheel; B band band switch |

Applicable machine tools | CNC Lathe & Turning Machinery and specially automatic equipment |

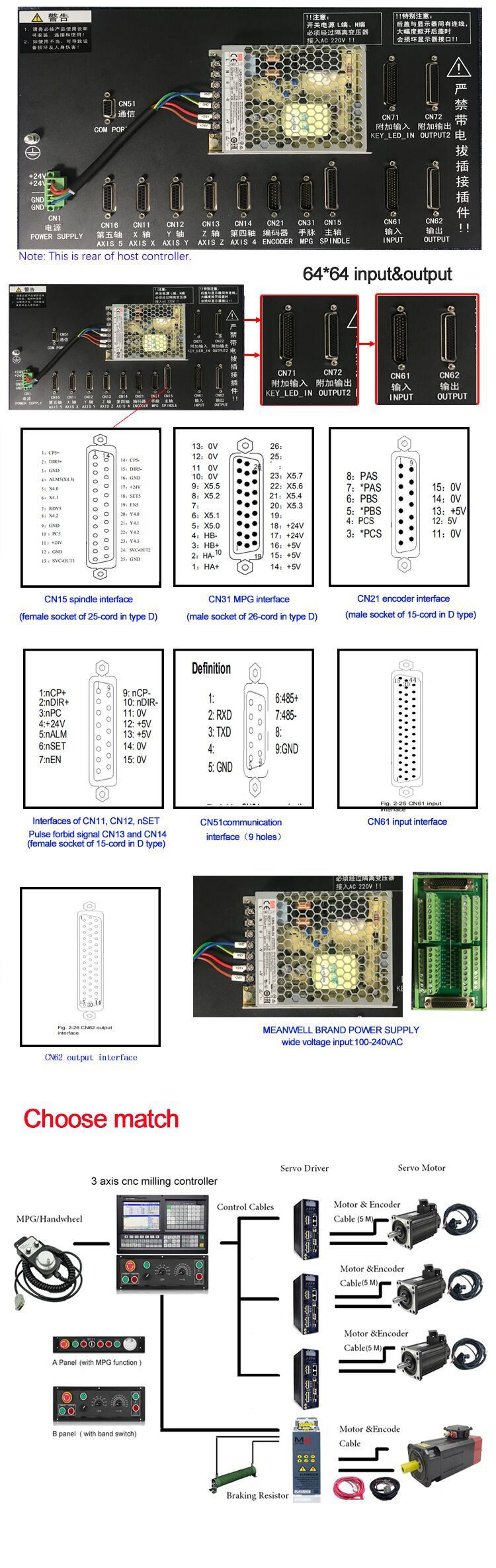

Control axis:

* Control axis: 3-5 axis (X, Y, Z,A,B)

* Interpolationaxis: Any 3 axis linear interpolation , any 2 axis circular interpolation

* Position command range:

Spindle axis functions:

* Two channels 0V ~ 10V analog voltage output, support double spindle control

* Spindle encoder: encoder lines can be set (100 p/r ~ 5000p/r)

* Encoder and spindle’s transmission ratio: (1 ~ 255):(1 ~ 255)

* Spindle ration: 50% ~ 120% eight stages real-time tunning in total

Tool functions:

* Tool length compensation

* Tool point radius compensation (C type)

* Two levels PLC programming, operation speed is 1.5μs/ step basic instruction; 4700 steps mostly, the cycle of the first level programming is 8ms.

* Support PLC warning and PLC alarm.

* Support multiply PLC programming (mostly 20), the current PLC programming can be chosen.

* 45 kinds of commands (10 kinds of basic commands, 35 kinds of function commands)

* I/O unit input/output: 32/32

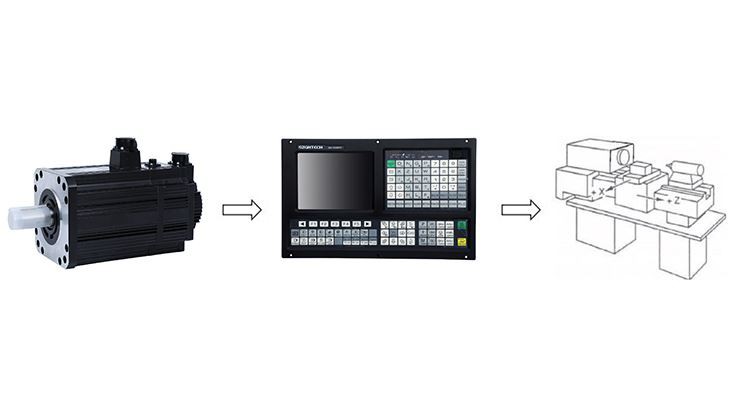

Related products:

1.CNC Controller

2,Axis servo motor &driver

3.Spindle Servo Motor&driver

4,Rotary table

Application: CNC Lathe & Turning Machinery and specially automatic equipment

More Professional service in cnc system total products exporting field

FAQ

Q: What’s your after-sale service?

A: Our quality warranty period is one year. Any quality problem will be solved to customer satisfactions.

Q: How can we get a quote?

A: Contact us with specification: such as power ,torque ,application,axis etc.

Q: What's the trade term and payment term?

A: Amount less than $1000, 100% paid before production, more than $1000 can be negotiated!

T/T, Western Union, PAYPAL etc.

If you have another question, pls feel free to contact us as below

Our company adheres to the service concept of precision service and customer first, strives to create the most professional and considerate service platform for customers, and gradually establishes a benchmark corporate style in the 2-Axis CNC Lathes (mm-Labturn 2028, MAXNOVO Machine) industry. We continue to optimize the layout of industrial structure, enhance the momentum of reform and innovation, and improve the level of operation and management. We combine the actual development of the enterprise with a realistic and pragmatic attitude and down-to-earth style to constantly reform, reorganize and innovate the property rights system, management system and operation system of the enterprise.