We will firmly grasp the central position of innovation in the overall reform and development, and continue to enhance our ac servo motor and driver, 7.5kw AC SERVO MOTOR AND DRIVER, 18.5kw ac servo spindle motor technology. We will be in line with the pragmatic cooperation attitude and flexible business strategy, welcome the new and old customers to visit us. We can provide tailor-made integrated services to meet customer needs in all aspects. The company's products have a competent foundation and credibility in terms of technology content and specifications. We will continue to provide high-quality products and services with first-class quality, advanced technology, satisfactory service and reasonable prices. We strive for customer acceptance with marketing, obtain customer recognition with products and services, and promote in-depth cooperation with customers with overall strength and focus on customer needs.

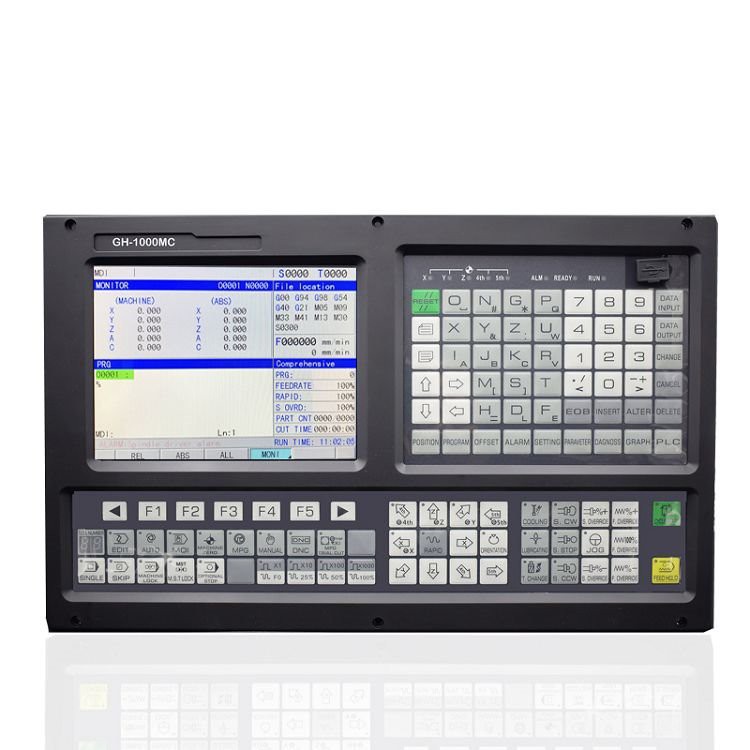

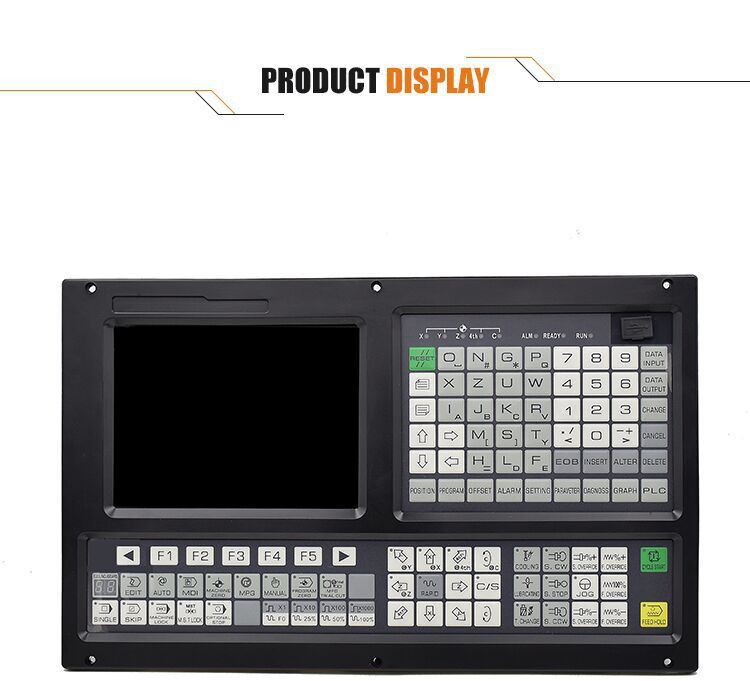

As siemens milling controller Support PLC ATC 3 Axis Milling CNC Machine Control system with USB

Number of control axes | 3axes (X,Y, Z) |

Minimum programming | 0.001mm |

Maximum programming | ± 99999.999mm |

Top speed | 30m / min |

Feed speed | 0.001-15m / min |

Manual continuous | One axis or simultaneous multi-axis |

Interpolation method | Straight line, arc, thread interpolation |

Tool offset | Length compensation, nose radius C compensation |

Spindle functions | Gear, dual analog control, rigid tapping |

Handwheel functions | Panel type, plug-in hand-held |

Screen saver function | Screen saver function |

Communication function | RS232, U disk interface |

Compensation function | Knife compensation, between compensation, screw compensation, radius compensation |

Program editing | Male / English, relative / absolute programming |

Limit function | Software limit, hardware limit |

Pre-reading function | Short line preprocessing 10,000 lines |

Password protection | Multi-level password protection |

Input and output | I / O point 24X24 |

PLC programming | The user is free to design PLC function |

Acceleration and deceleration control | Linear acceleration and deceleration, the number of additions and subtractions |

Encoder lines | Any setting |

User macro program | Yes |

Electronic gear functions | Yes |

Number of control axes | 3axes (X, Y, Z) |

Minimum programming | 0.001mm |

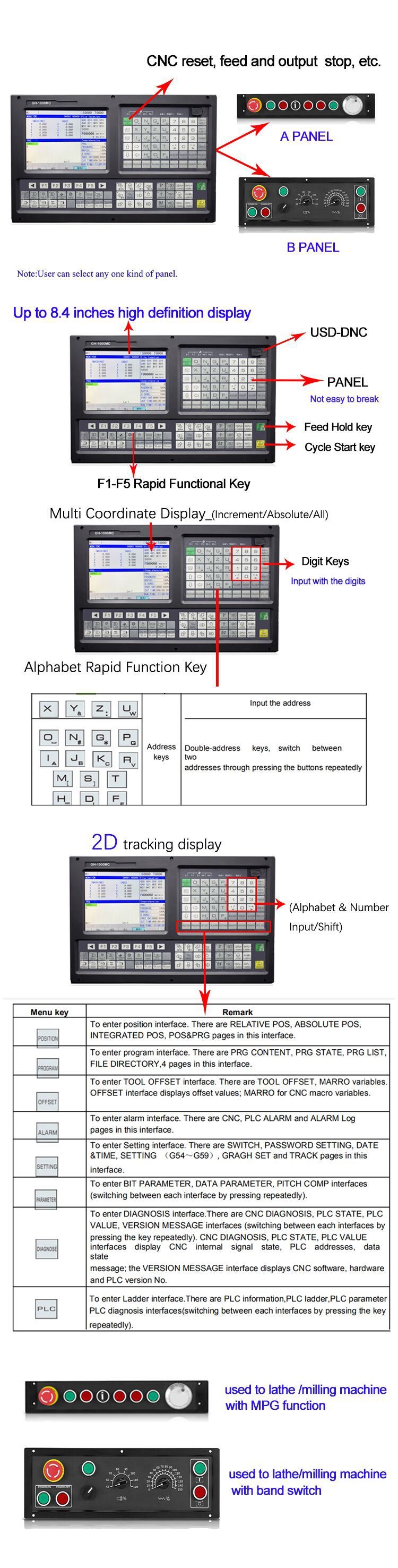

* Control axis: 3-5 axis (X, Y, Z,A,B)

* Interpolationaxis: Any 3 axis linear interpolation , any 2 axis circular interpolation

Spindle axis functions:

* Two channels 0V ~ 10V analog voltage output, support double spindle control

* Spindle encoder: encoder lines can be set (100 p/r ~ 5000p/r)

* Encoder and spindle’s transmission ratio: (1 ~ 255):(1 ~ 255)

Tool functions:

* Tool length compensation

* Tool point radius compensation (C type)

Precision compensation:

* Thread pitch error compenstation: Compensation points, compensation interval, compensate original position can be set.

* Backlash compensation: can set reverse interval to interpolation machine tool by fixed frequency or lifting speed mode.

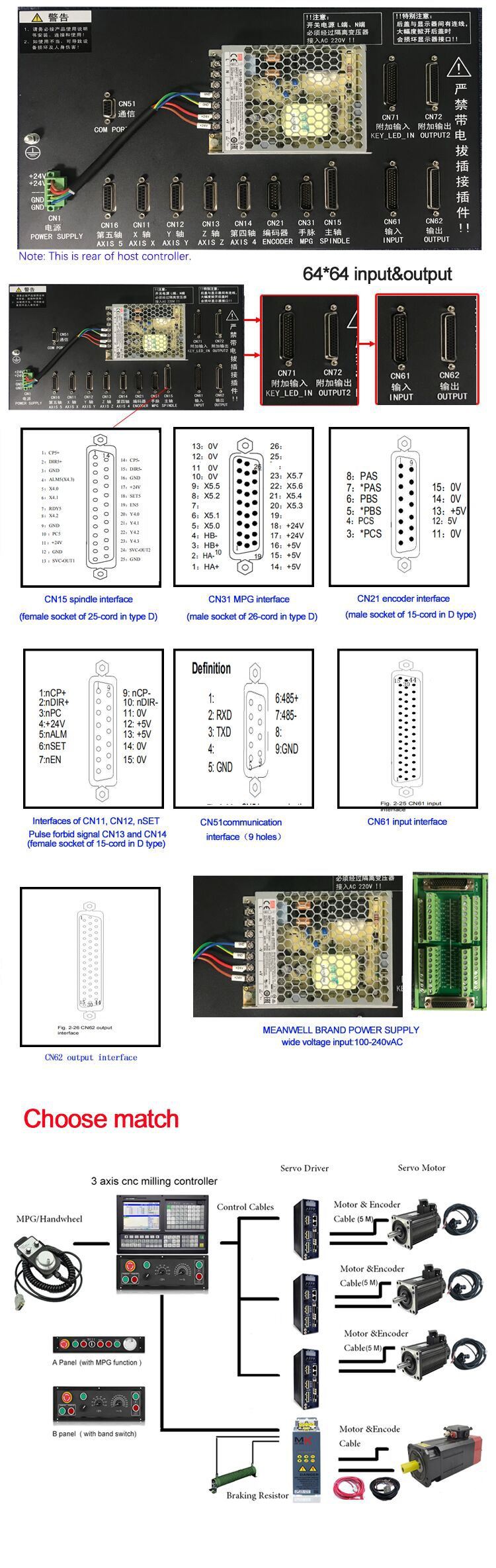

Related products:

2,Axis servo motor &driver

3.Spindle Servo Motor&driver

4,Rotary table

High quality products&Professional service

FAQ

Q: Which payment form you can accept?

A: T/T, Western Union, PayPal etc. We accept any convenient and swift payment term.

Q: Which certificate do you have?

A: CE and ER

Q: Do you have the test and audit service?

A: Yes, we can assist to get the designated test report for product and the designated factory audit report.

If you have another question, pls feel free to contact us as below

Our primary objective is usually to offer our shoppers a serious and responsible small business relationship, offering personalized attention to all of them for China Factory 808di 2 Axis CNC Lathe Controller. Establishing a good brand image is of great significance to improve cohesion and enhance the sense of belonging of employees. We carry out the plate, professional, lean management, so as to create an upgraded version of the industry.