With the rapid development of science and technology and industrial production, product quality is becoming more and more a key factor for the success of enterprises, therefore, we also pay more and more attention to the quality of our 37KW Servo Spindle Driver, 3800W Ac Servo Motor And Driver, servo motor 2KW. We have always been committed to optimizing business management, achieving innovation, and striving to be an excellent enterprise in the industry. The company takes "pioneering, dedication, integrity and effectiveness" as the spirit of enterprise. Our technical service network covers all major cities across the country, and we are committed to serving our customers promptly and quickly. The company has a beautiful, comfortable environment, advanced production equipment, strong technical force, and constantly introduces advanced foreign technology and management models, facilities and processes have been recognized by customers at home and abroad.

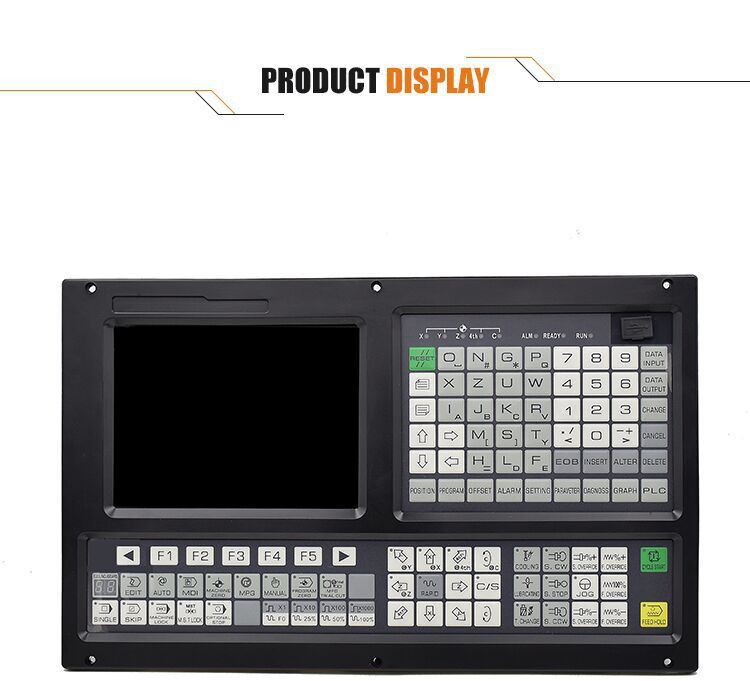

4 axis milling CNC controller kit Support ATC+PLC+Macro+Scanning for welding consumables

magnet drill machine

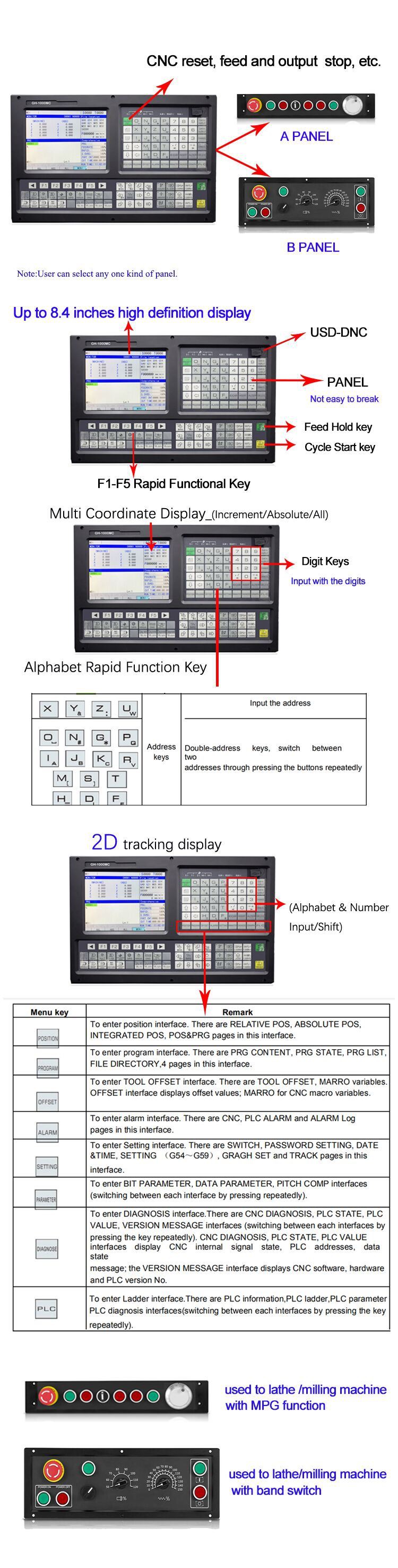

1)4 Axis Fully English Type CNC milling controller

2) 800x600 8.4 inch real color LCD displayer

3) Electric Turret & Binary code turret,Max: 99 pcs tools

4) Support ATC , Macro function and PLC function

5) Max speed is 60m/min, feeding speed is 24m/min,0.1um control precision

6) Adapted servo spindle can realize spindle continous position,rigid tapping,rigid screw processing

7) High anti-jamming switch power(100V-240VAC 50Hz/60Hz -> 24VDC)

8) 64MB Memory , 56Mb user store room

9) With USB interface,it supports file operation in flash disk,system configuration and software upgrade

10) Position Control Mode:Pulse+Direction/AB Phase,Dual Analog voltage output of 0~10V

11) 32 bits ARM microprocessor+FPGA Technology.

12) Basic I/O: 36X36 , can be edited freely

13) Cutter offset : C

GH lathe CNC system adopts 32 bit high performance industrial grade CPU and CPLD chip of super large scale programmable gate array to form the control core, and realize μm level precision motion control. The system has strong function, stable performance, intuitive and simple interface display and convenient operation.

FAQ

Q: Do you support customized manufacturing?

A: Yes,we can customized manufacturing according to customer's requirment. We support to OEM your own company display interface and logo.

Q: How long is your delivery time?

A: Generally it is 3-5 days if the goods are in stock. or it is 5-10 days if the goods are not in stock, it is according to quantity.10-20 days if customized manufacturing.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample with sample price.

If you have any other question, pls feel free to contact us as below

Adhering into the basic principle of 'quality, assistance, effectiveness and growth', we have attained trusts and praises from domestic and worldwide client for Hr 60 Hydraulic Speed Controller for CNC Drilling Machine Replace Kinechek Hydro Check. Our company has earned a good reputation around the globe for our advanced technology, superior quality electric motor products, and efficient after-sale service. We have made every effort to make our products be available to every market. We actively seize the strategic opportunities and make use of our own advantages to make the enterprise development to a higher level.