We mainly commit to the integrated demand and supply of 5 Axis Cnc Lathe Controller, 2400mm Spraying Robot Arm, 3.7KW Servo Spindle Driver for domestic and foreign enterprises, relying on a mature supply chain system, customer management system and strong capital support. We win the trust of users with a good reputation, and create value for customers and create opportunities for employees. We are looking forward to work with you for a win-win situation. We always adhere to the principle of quality first and customer first, moving towards the development direction of 'specialization, scale and internationalization', and have gradually become one of the professional companies with reputation at home and abroad.

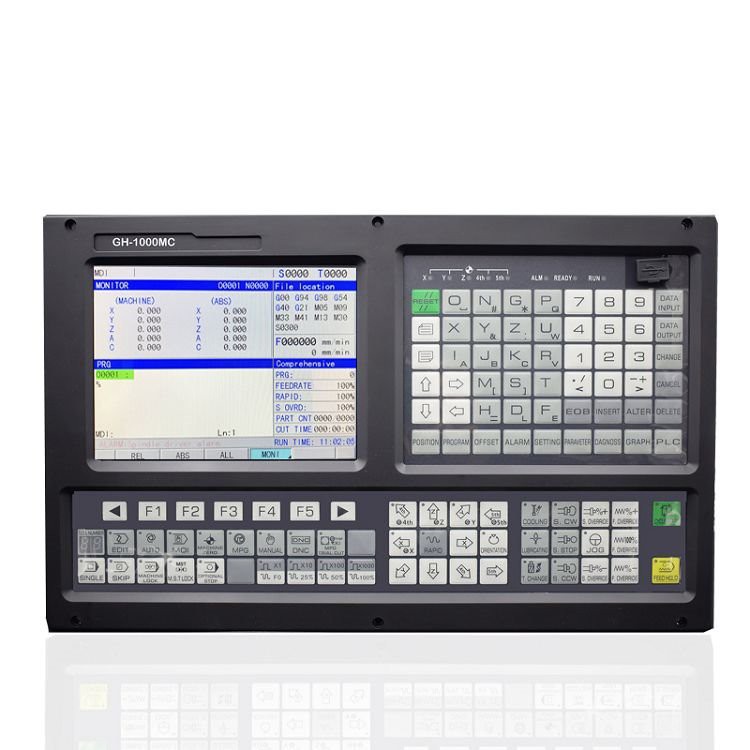

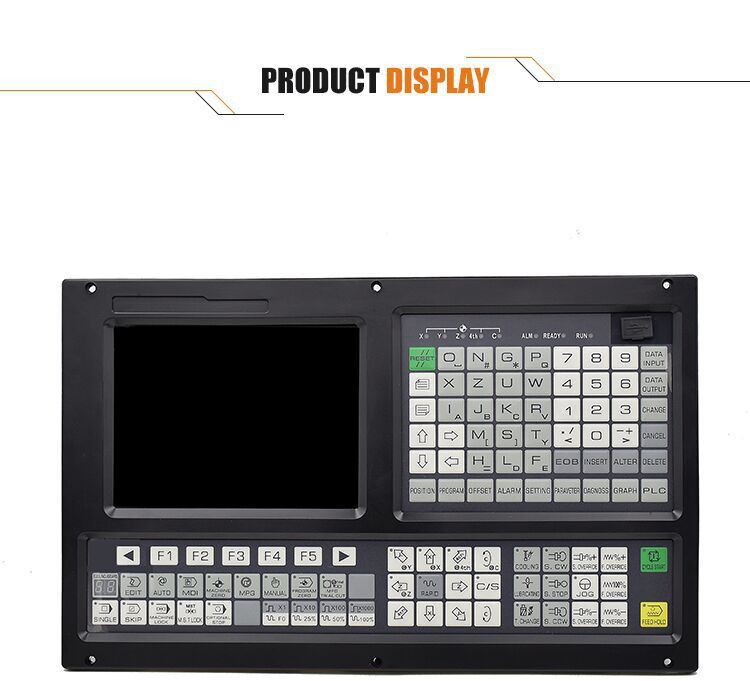

As siemens milling controller Support PLC ATC 3 Axis Milling CNC Machine Control system with USB

Number of control axes | 3axes (X,Y, Z) |

Minimum programming | 0.001mm |

Maximum programming | ± 99999.999mm |

Top speed | 30m / min |

Feed speed | 0.001-15m / min |

Manual continuous | One axis or simultaneous multi-axis |

Interpolation method | Straight line, arc, thread interpolation |

Tool offset | Length compensation, nose radius C compensation |

Spindle functions | Gear, dual analog control, rigid tapping |

Handwheel functions | Panel type, plug-in hand-held |

Screen saver function | Screen saver function |

Communication function | RS232, U disk interface |

Compensation function | Knife compensation, between compensation, screw compensation, radius compensation |

Program editing | Male / English, relative / absolute programming |

Limit function | Software limit, hardware limit |

Pre-reading function | Short line preprocessing 10,000 lines |

Password protection | Multi-level password protection |

Input and output | I / O point 24X24 |

PLC programming | The user is free to design PLC function |

Acceleration and deceleration control | Linear acceleration and deceleration, the number of additions and subtractions |

Encoder lines | Any setting |

User macro program | Yes |

Electronic gear functions | Yes |

Number of control axes | 3axes (X, Y, Z) |

Minimum programming | 0.001mm |

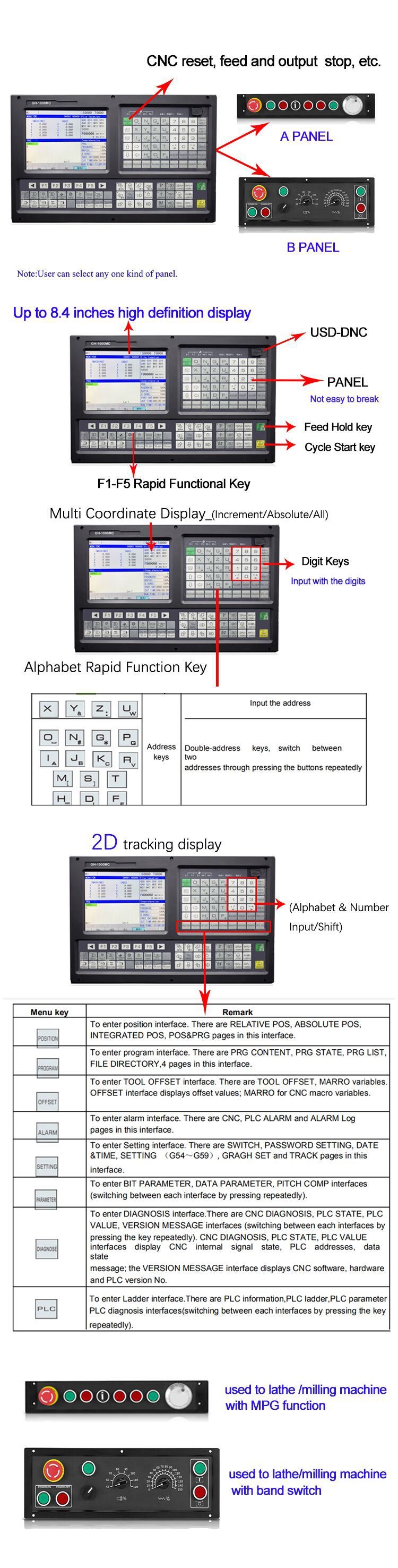

* Control axis: 3-5 axis (X, Y, Z,A,B)

* Interpolationaxis: Any 3 axis linear interpolation , any 2 axis circular interpolation

Spindle axis functions:

* Two channels 0V ~ 10V analog voltage output, support double spindle control

* Spindle encoder: encoder lines can be set (100 p/r ~ 5000p/r)

* Encoder and spindle’s transmission ratio: (1 ~ 255):(1 ~ 255)

Tool functions:

* Tool length compensation

* Tool point radius compensation (C type)

Precision compensation:

* Thread pitch error compenstation: Compensation points, compensation interval, compensate original position can be set.

* Backlash compensation: can set reverse interval to interpolation machine tool by fixed frequency or lifting speed mode.

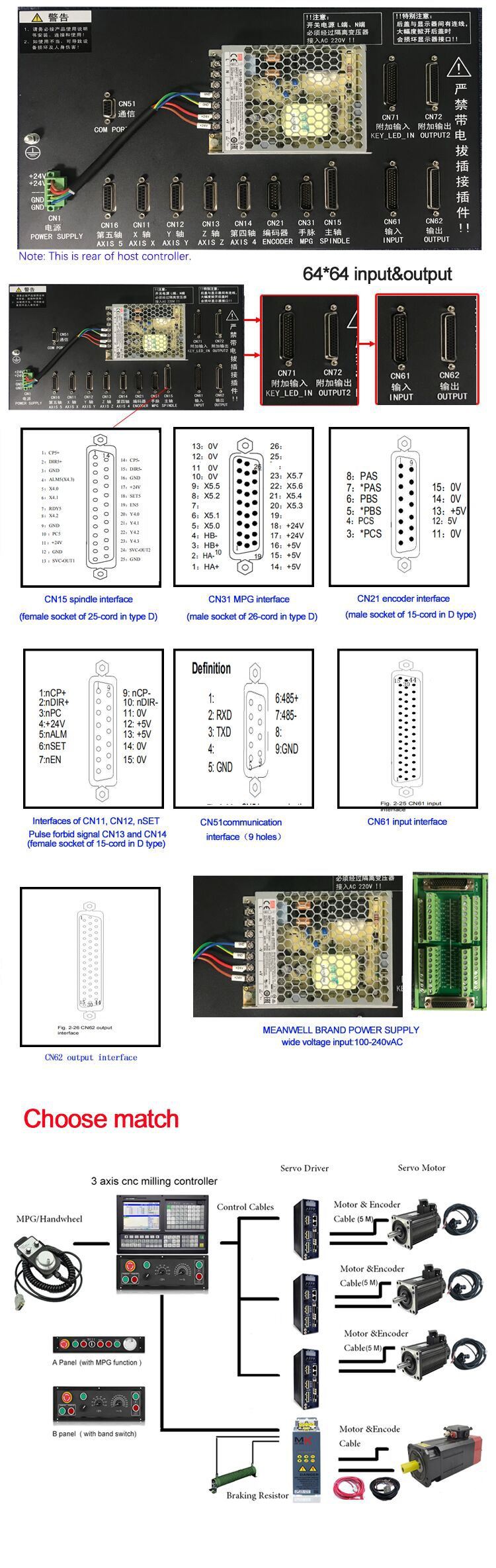

Related products:

2,Axis servo motor &driver

3.Spindle Servo Motor&driver

4,Rotary table

High quality products&Professional service

FAQ

Q: Which payment form you can accept?

A: T/T, Western Union, PayPal etc. We accept any convenient and swift payment term.

Q: Which certificate do you have?

A: CE and ER

Q: Do you have the test and audit service?

A: Yes, we can assist to get the designated test report for product and the designated factory audit report.

If you have another question, pls feel free to contact us as below

Adhering to technology leadership, taking the development path of combining production, teaching and research, and continuously committing to Precision Hydraulic Chuck 6 Station Turret Slant Bed CNC Lathe Tck6340 industry with Chinese characteristics are our biggest characteristic advantages and directions since our development. Relying on professional R&D technology, diversified and high-quality products and fast and thoughtful service system, our company continues to meet and exceed the growing needs of customers. Constantly surpass and pursue perfection.