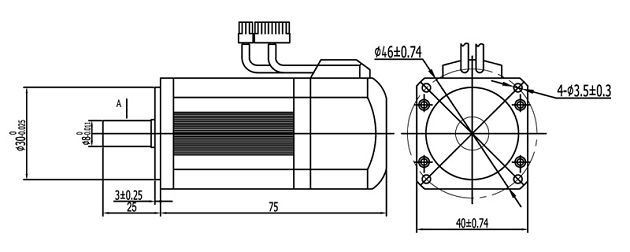

Mini three-phase 100W 0.32NM AC Servo Motor and Driver

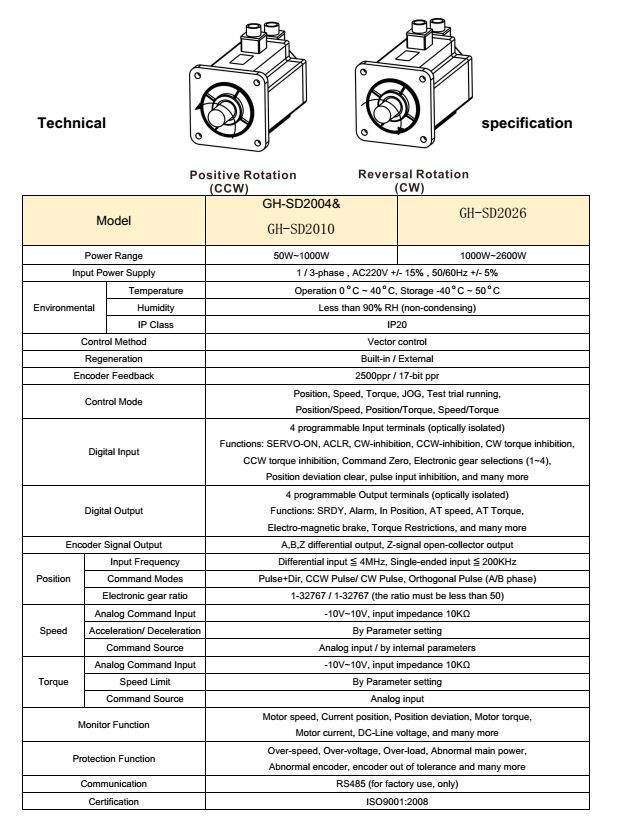

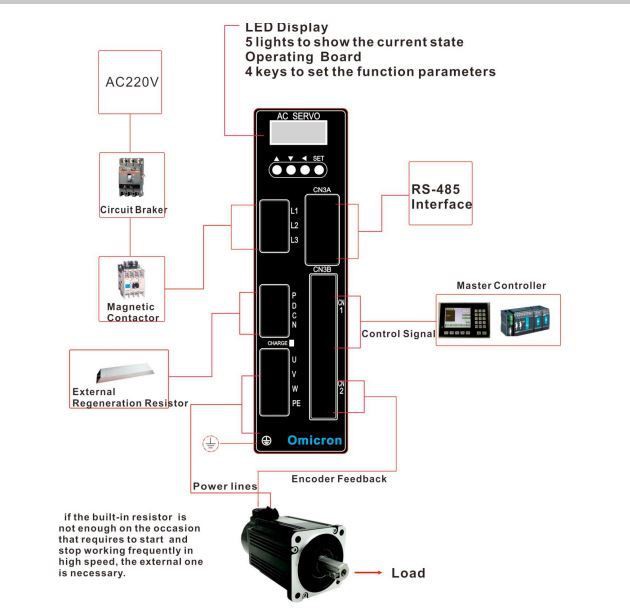

Servo motor series are wide output range from 50W to 7500W, it is ideal for cost sensitive applications specially, GH provide complete servo motor series including the low-inertia , middle-inertia and high- inertia servo,with high precision and stability.

Other special requirements,please contact with our technology team to negotiate.

Mini three-phase 100W 0.32NM 3000RPM AC Servo Motor and Driver Suitable for Sewing Machines

Specifications

Rated Voltage (V): 220

Rated Current (A): 1.5

Rotor Inertia (kg.m2x10-4): 0.17 Application Environment:

Work temperature: 0°C ~ 40°C

Relative Humidity: < 90% RH

Altitude : < 1000 m

Non corrosive ,non flammable gas and dust and oil-mist

Features

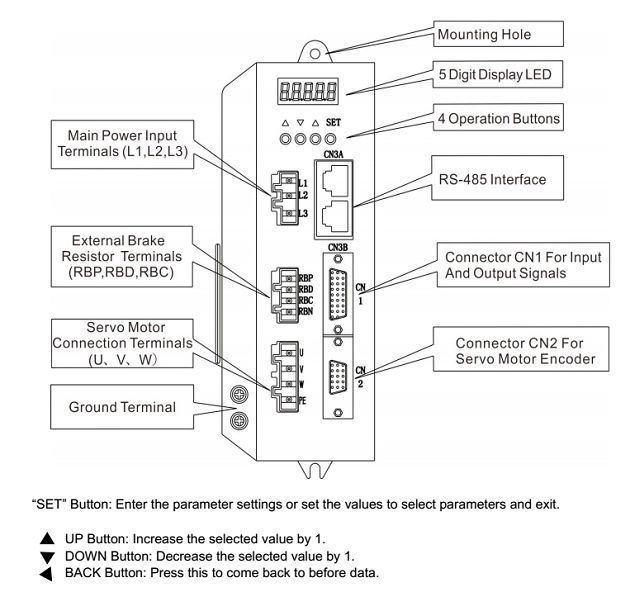

GH-04010D is 100W servo motor, and come with standard 2500 line, matching with our servo driver, and wide variety of options are available for customization to meet your application needs.

The match servo driver SD2004,that matching for 50W servo motor.

There is also one dual servo driver,GH-202,that can control two pcs of 50W servo motors synchronously.

Application

CNC Machinery,printing equipment, packaging equipment, textile equipment, laser processing equipment, robotics, automated production lines, such as processing precision, processing efficiency and reliability, and other requirements of the relatively high equipment.

1.Industrial packing: plastic bag +foam boxes+ carton +wooden pallets

2.Commercial packing: plastic bag+ foam boxes + carton

3.As the clients’ requirement

Delivery Detail: Normally ready goods and stock within 2-5days

FAQ

Q: Do you support customized manufacturing?

A: Yes,we can customized manufacturing according to customer's requirment. We support to OEM your own company display interface and logo.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample with sample price.